3D Print Warping: Why It Happens and How to Fix It

Do your 3D prints often come out distorted or uneven than intended? You may be experiencing 3D print warping. Warping happens for several reasons and is often frustrating for many people. But why does it happen in the first place, and how to prevent warping 3d printing? This blog sets out to explain this in detail.

Most Common Causes of 3D Print Warping

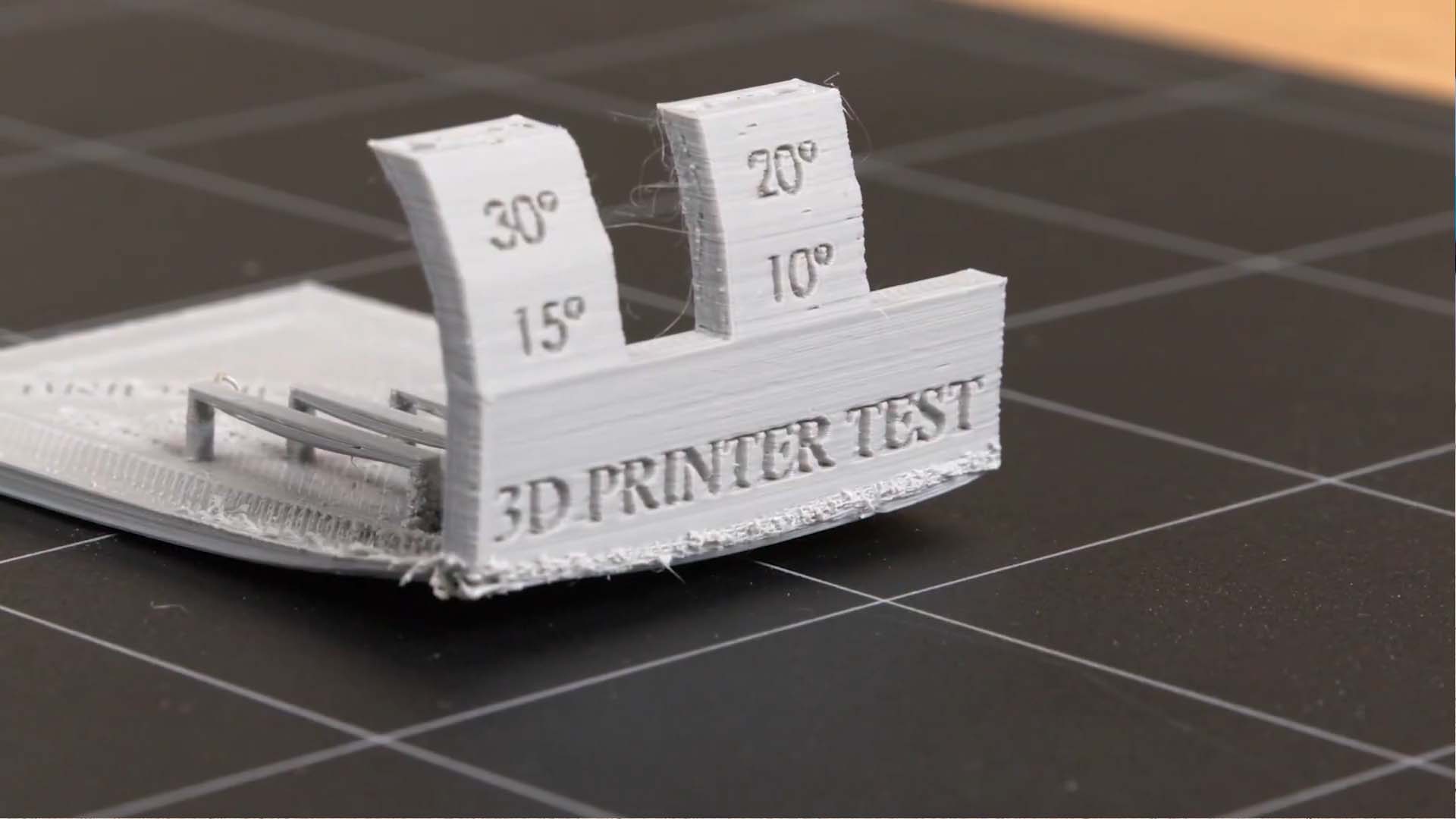

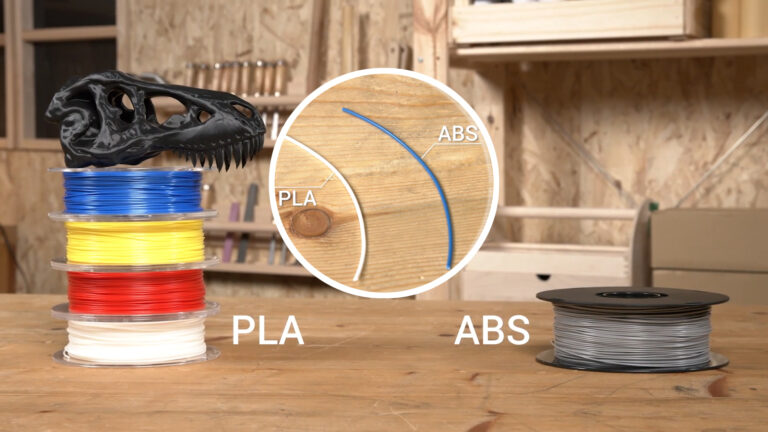

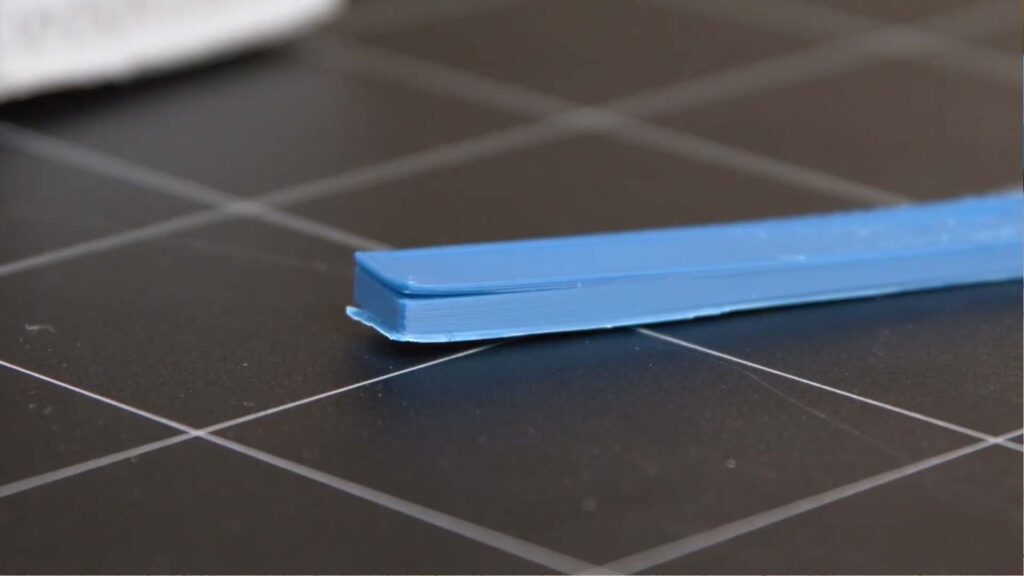

The reason why parts of a 3D print warp is their uneven cooling. The plastic, as it cools, contracts. If the lower layers cool and contract when the upper layers are still warm, the internal stress can make it lift or warp, particularly around the corners. It must be noted, however, that the thermal contraction and expansion depend on the filament type.

Let’s dive slightly deeper into each of the causes of warping.

Bed Adhesion Issues

- Uneven bed leveling: An unleveled bed leads to inconsistent first layer adhesion, making the print more susceptible to warping.

- Dirty or oily build plate: Contaminants on the build plate can prevent the filament from sticking properly, leading to lifting and warping.

- Inappropriate bed surface material: Different materials adhere better to different build surfaces.

Temperature Problems

- Inconsistent bed temperature: The heated bed should remain at a consistent temperature to prevent warping. If the bed is too cold, the print might warp or detach.

- Drafts and ambient temperature fluctuations: Fluctuations in room temperature can lead to warping, especially for temperature-sensitive materials like ABS.

- Incorrect nozzle temperature: While primarily affecting extrusion, incorrect nozzle temperature can indirectly contribute to warping by affecting layer adhesion.

Print Settings

- Insufficient or incorrect first layer settings: The first layer is the foundation. An incorrect nozzle distance or printing too fast can lead to poor adhesion and subsequent warping.

- Lack of brim or raft: Brims and rafts increase the surface area in contact with the build plate, improving adhesion and helping to prevent corners from lifting.

- Infill patterns and density: While not a primary driver of warping, using very high infill densities or certain infill patterns that cause significant internal stress during cooling could potentially contribute to the issue.

How to Prevent 3D Print Warping

Having understood the reasons behind the warping of 3D printing, it is time to look at practical steps that can be taken to prevent it and have the prints well-bedroomed on the build plate.

Optimizing Bed Adhesion

- Thorough bed leveling techniques. This involves ensuring the nozzle is the same distance from the bed at all points. Many modern printers have auto-leveling, and the Snapmaker does. For manual leveling, a piece of paper can be used to gauge the correct distance.

- Cleaning the build plate effectively. Cleaning the bed with isopropyl alcohol before each print to remove any oils or debris.

- Choosing the right bed surface.

- Glass beds can provide a very smooth and flat surface, often requiring adhesion aids for good grip.

- PEI (Polyetherimide) sheets offer excellent adhesion for a wide range of materials, especially when heated. Textured PEI often works well for PLA, PETG, and ABS. However, printing highly adhesive filaments like PETG and TPU on the smooth PEI plate is not recommended.

- Painter’s tape is a cost-effective option, particularly for PLA. Apply it smoothly to your build plate, ensuring no air bubbles.

- Using adhesion aids. These can provide an extra layer of adhesion, especially for materials prone to warping.

- Glue sticks (PVA-based) can create a slightly tacky surface that helps the first layer stick. Apply a thin, even layer to the build plate.

- Hairspray can also provide a sticky surface. Apply a light, even coat to the build plate before heating.

Controlling Temperature

- Maintaining a consistent bed temperature: Use your slicing software to set the recommended bed temperature for your filament. Ensure your printer’s bed heating element is functioning correctly and maintaining a stable temperature throughout the print.

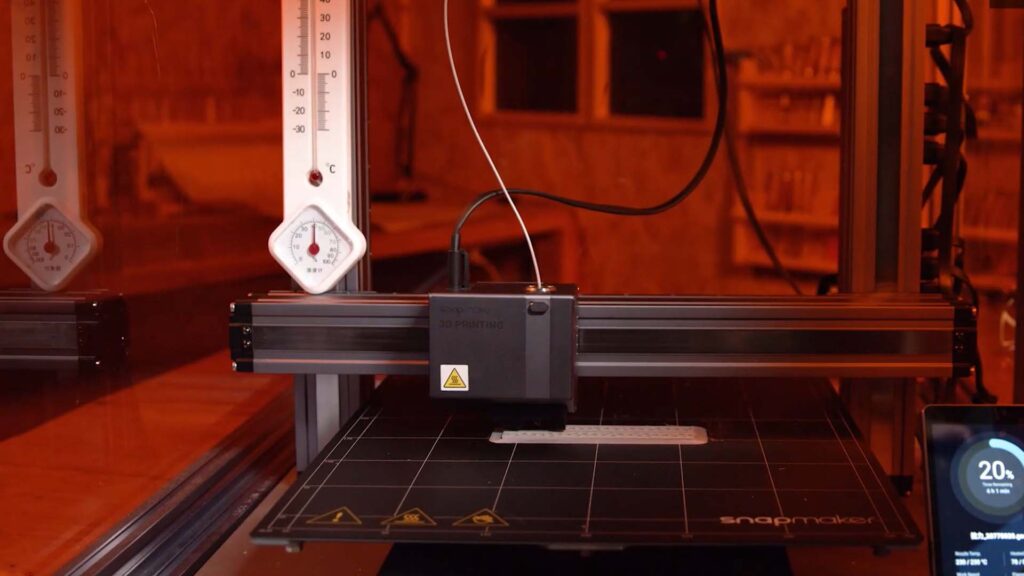

- Enclosing your 3D printer: For materials like ABS that are highly susceptible to warping due to temperature fluctuations, an enclosure is highly recommended. This helps to trap heat, creating a more stable ambient temperature around the print and preventing drafts. You can purchase purpose-built enclosures or even create your own DIY version.

- Adjusting ambient temperature if necessary: Try to print in a room where the temperature is relatively stable and within the recommended range for your filament (e.g., 20-25°C for PLA). Avoid placing your printer near open windows or air conditioning vents.

Slicing Software Settings

- Optimizing first layer height and width: Setting the initial layer height slightly higher than subsequent layers can improve adhesion by ensuring more contact with the build plate. Similarly, increasing the first layer width can also enhance adhesion.

- Utilizing brims and rafts effectively:

- Brims are excellent for preventing corners from lifting on parts with a large, flat base. They are relatively easy to remove after printing.

- Rafts provide a completely separate foundation for your print, which can be particularly useful for complex geometries or when printing materials known to warp. However, they do use more filament and require removal.

- Experimenting with different infill patterns: While not a direct fix for warping, try using infill patterns that might introduce less stress during cooling, such as rectilinear or gyroid. Lowering the infill density for the initial layers might also be worth experimenting with.

Fixing PLA Warping & ABS Warping

PLA is generally easier to print but can still warp, especially in larger prints, due to cooling and contraction. ABS is more prone to warping due to its higher printing temperature and greater thermal contraction.

- At what temperature does PLA warp? PLA can start to lose form above its glass transition temperature, which is around 60°C. While it won’t melt until 150-160°C, maintaining a bed temperature within the recommended range (often 25-60°C) is crucial to prevent warping

- How do I keep my PLA prints from warping so big? PLA larger prints need excellent bed adhesion (such as a textured PEI sheet), a consistent bed temperature (use cooling fans appropriately to prevent excessive heat buildup), and potentially using a brim or raft.

- At what temperature does ABS bend? ABS bends when heated past its glass transition temperature, which is around 101°C. To avoid warping, a bed temperature range of 80˚C–100˚C is recommended.

- How to keep large ABS prints from warping? Printing large ABS effectively requires a heated bed (around 100°C) and an enclosure to maintain a stable temperature and prevent drafts.

Conclusion

Warping is a condition that most people hate and unpleasant in 3D printing. This occurs due to uneven cooling resulting in contraction and deformation of some materials. Improper bed adhesion, mismatched temperature readings, and wrong setting configurations will cause prints to lift off the bed or even cause warping on the corners of the print.

Various improvements to adhesion, fine-tuning the conditions of the environment during printing, and altering slicing settings could help to minimize print warping and advance their quality. Also, minor changes like leveling the bed, using adhesion agents, and encasing your printer could make a huge difference, especially when dealing with things like ABS and PLA.