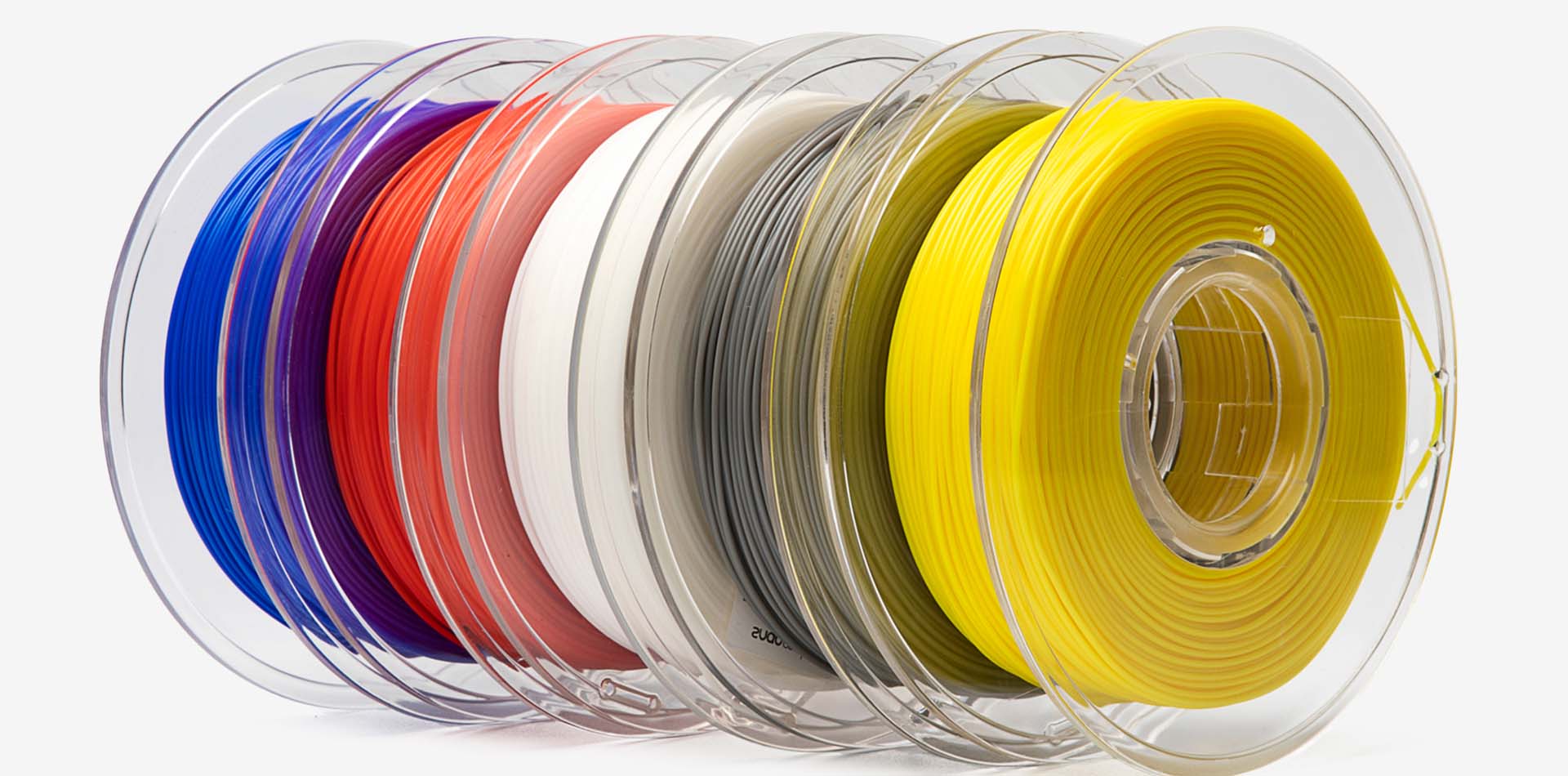

3D Printer Filament Types

Filaments are the foundation of FDM (Fused Deposition Modeling) 3D printing. While PLA remains the most popular choice, the world of 3D printing materials is vast and diverse, offering solutions for nearly every printing challenge.

This guide will introduce the properties of various FDM 3D printing filaments, from everyday plastics to specialized materials.

What Types of 3D Printer Filaments Are There?

The accessibility and improving print quality of FDM 3D printers have fueled a growing demand for filaments. Let’s look into the details of popular choices:

PLA (Polylactic Acid)

- Ease of Printing: Very Easy. Often considered the easiest to print, requiring lower temperatures and generally forgiving with printer settings. It’s less prone to warping than most other common filaments.

- Strength: Moderate. Good for general-purpose prints and prototypes, but not as strong as ABS or PETG.

- Flexibility: Low. Typically quite rigid and can be brittle.

- Durability: Medium. Suitable for indoor use and decorative items, but can degrade with prolonged UV exposure or high temperatures.

- Temperature Resistance: Low (around 50-60°C / 122-140°F). Not ideal for parts that will be exposed to significant heat.

- Typical Applications: Prototyping, educational projects, decorative items (vases, figurines), tools that won’t experience high stress or temperature.

You can find high-quality PLA filament in the Snapmaker Store.

ABS (Acrylonitrile Butadiene Styrene)

- Ease of Printing: Medium to Difficult. More challenging than PLA due to its tendency to warp, especially with larger prints. Requires a heated bed and often an enclosure to maintain a consistent temperature.

- Strength: Good. Stronger and more impact-resistant than PLA.

- Flexibility: Medium. Offers a bit more flexibility than PLA but is still relatively rigid.

- Durability: High. Good for functional parts that need to withstand wear and tear.

- Temperature Resistance: Medium (around 80-100°C / 176-212°F). Higher than PLA, making it suitable for some warmer environments.

- Typical Applications: Functional prototypes, mechanical parts (gears, clips), enclosures, toys, items that need to be durable and heat-resistant (within its limits).

You can find high-quality ABS filament in the Snapmaker Store.

PETG (Polyethylene Terephthalate Glycol-modified)

- Ease of Printing: Easy to Medium. Generally easier to print than ABS, with better layer adhesion and less warping. Often considered a good compromise between PLA and ABS.

- Strength: Good to High. Stronger and more impact-resistant than PLA, approaching or sometimes exceeding ABS in certain aspects.

- Flexibility: Medium to High. More flexible than both PLA and ABS, offering a good balance of rigidity and flexibility.

- Durability: High. Excellent wear resistance and good resistance to chemicals and moisture.

- Temperature Resistance: Medium (around 70-80°C / 158-176°F). Better than PLA but generally slightly lower than ABS.

- Typical Applications: Functional parts, mechanical components, robotics, waterproof items (bottles, containers), food-safe containers (check specific formulations).

You can find high-quality PETG filament in the Snapmaker Store.

Nylon (Polyamide)

- Ease of Printing: Medium to Difficult. Can be challenging due to its tendency to absorb moisture (hygroscopic), which affects print quality. Often requires higher printing temperatures, a heated bed, and careful storage.

- Strength: Very High. Known for its exceptional tensile strength and abrasion resistance.

- Flexibility: High. Significantly more flexible than PLA, ABS, and PETG.

- Durability: Very High. Excellent wear and tear resistance, making it ideal for demanding applications.

- Temperature Resistance: Medium to High (can vary depending on the type of Nylon, typically 80-120°C / 176-248°F or higher).

- Typical Applications: Gears, hinges, bearings, functional parts requiring high strength and flexibility, wear-resistant components (tool handles).

You can find high-quality nylon filament in the Snapmaker Store.

TPU/TPE (Thermoplastic Polyurethane/Thermoplastic Elastomer)

- Ease of Printing: Medium to Difficult. Can be challenging due to its flexibility, which can cause issues with filament feeding, especially in Bowden-style extruders. Direct drive extruders are generally recommended. Printing speeds are often slower.

- Strength: Low to Medium. Strength varies depending on the Shore hardness, but generally not as strong as rigid filaments.

- Flexibility: Very High. Extremely flexible and elastic, with rubber-like properties.

- Durability: Medium to High. Good abrasion and tear resistance.

- Temperature Resistance: Low to Medium (typically around 60-80°C / 140-176°F).

- Typical Applications: Phone cases, gaskets, belts, seals, flexible joints, wearable electronics.

You can find high-quality TPU filament and high flow TPU95 in the Snapmaker Store.

Specialty 3D Printer Filaments

The world of 3D printing filaments is diverse. Beyond the common filaments used for everyday products, a wide range of options exists. Some specialty filaments have been developed to meet niche but considerable application needs:

Carbon Fiber Filled (typically PLA or ABS base)

- Strength: Very High. Significantly stronger and stiffer than the base material.

- Ease of Printing: Medium. Can be abrasive, requiring hardened steel nozzles to prevent wear. May have slightly different temperature requirements than the base material.

- Applications: High-strength, lightweight structural components, drone parts, tools.

Wood PLA

- Strength: Similar to PLA.

- Ease of Printing: Easy to Medium. Generally prints similarly to PLA but may require adjustments to temperature and retraction. Can be brittle.

- Applications: Aesthetic prints with a wood-like appearance, decorative items, models.

You can find high-quality wood PLA filament in the Snapmaker Store.

Metal Filled (typically PLA base)

- Strength: Similar to PLA, but with added weight and density.

- Ease of Printing: Medium to Difficult. Can be abrasive, requiring hardened nozzles. Often requires post-processing (polishing, tumbling) to achieve a metallic shine.

- Applications: Decorative items with a metallic look and feel, jewelry, props.

Polycarbonate (PC)

- Strength: Very High. Exceptionally strong and impact-resistant.

- Ease of Printing: Difficult. Requires very high printing temperatures (often above 270°C), a heated bed (above 100°C), and an enclosed printer to prevent warping and ensure layer adhesion.

- Applications: Engineering prototypes, functional parts requiring high strength and temperature resistance.

ASA (Acrylonitrile Styrene Acrylate)

- Strength: Similar to ABS.

- Ease of Printing: Medium. Similar to ABS in printing requirements but generally has better UV resistance and less warping.

- Applications: Outdoor applications, automotive parts, items exposed to sunlight.

PVA (Polyvinyl Alcohol)

- Strength: Low.

- Ease of Printing: Easy to Medium. Can be sensitive to moisture and may require specific storage conditions.

- Applications: Water-soluble support material for complex PLA or ABS prints.

You can find high-quality PVA filament in the Snapmaker Store.

HIPS (High Impact Polystyrene)

- Strength: Similar to ABS.

- Ease of Printing: Medium. Similar to ABS in printing requirements.

- Applications: Support material for ABS (dissolvable in limonene), can also be used for standalone prints with properties similar to ABS.

Flexible PLA

- Strength: Medium.

- Ease of Printing: Easy to Medium. Easier to print than TPU/TPE while still offering some flexibility.

- Applications: Semi-flexible parts, phone cases, gaskets.

Glow-in-the-Dark (various base materials)

- Strength: Similar to the base material.

- Ease of Printing: Similar to the base material, may be slightly more abrasive.

- Applications: Novelty items, safety markers, artistic prints.

You can find high-quality glow-in-the-dark green PLA filament in the Snapmaker Store.

Conductive Filament (typically PLA base)

- Strength: Similar to PLA.

- Ease of Printing: Easy. Prints similarly to PLA.

- Applications: Low-voltage electronic circuits, sensors, interactive prototypes.

Flame Retardant Filament (various base materials)

- Strength: Varies depending on the base material.

- Ease of Printing: Similar to the base material.

- Applications: Parts requiring fire safety, enclosures for electronics.

What is the Best Filament for 3D Printing?

There’s no single “best” filament – the ideal choice depends entirely on your specific purpose.

To choose the right filament, first ask yourself: What will the object be used for? Is it a decorative item, functional part, prototype, tool, or something for outdoor use? Then decide on the required properties:

- Strength and Durability: For objects needing to withstand stress or repeated use, choose ABS, PETG, Nylon, or Polycarbonate.

- Flexibility: For objects requiring bending or acting as seals, use TPU or TPE. Flexible PLA offers a milder flexibility.

- Temperature Resistance: For heat-exposed objects, select ABS, PETG, ASA, Nylon, or Polycarbonate. Avoid PLA in high-temperature environments.

- Special Considerations: Consider chemical resistance, water resistance, food safety, and UV resistance based on your specific application.

Next, consider the capabilities of your printer:

- Nozzle temperature limits

- Presence of a heated bed

- Printer enclosure

- Extruder type

- Nozzle material (especially for abrasive filaments)

Final Words

While dedicated filament manufacturers offer a wider variety, 3D printer companies often provide a more “plug-and-play” experience with filaments optimized for their machines. Also note that even for the same nominal type of filament (like standard PLA), the exact chemical formulation can vary between different brands, impacting print quality and material properties.

Snapmaker is going to release a batch of new filaments around June, so stay tuned for more exciting material options!