Blue Laser vs Red Laser: Which One Is Best for You

Today, let’s discuss the difference between blue and red laser.

Blue Laser vs Red Laser: Understanding the Differences

Laser wavelength is the main factor influencing the efficiency of different applications. There is a difference between working with blue laser vs red laser in the laser engraving process regarding accuracy, material compatibility, and efficiency.

There are laser wavelength differences between the two. This means that blue laser, which has a shorter wavelength, will therefore suit applications demanding extremely high accuracies and a very high requirement for precision of measurement. On the other hand, red laser, which has a comparatively long wavelength, is suitable for dynamic applications and very high-speed measurements—for instance, measuring moving items on conveyor belts.

What Determines Laser Color and Performance?

Laser color and performance are defined by the wavelength of light they emit. Blue lasers have shorter wavelengths than red lasers, leading to distinct laser wavelength differences in functionality.

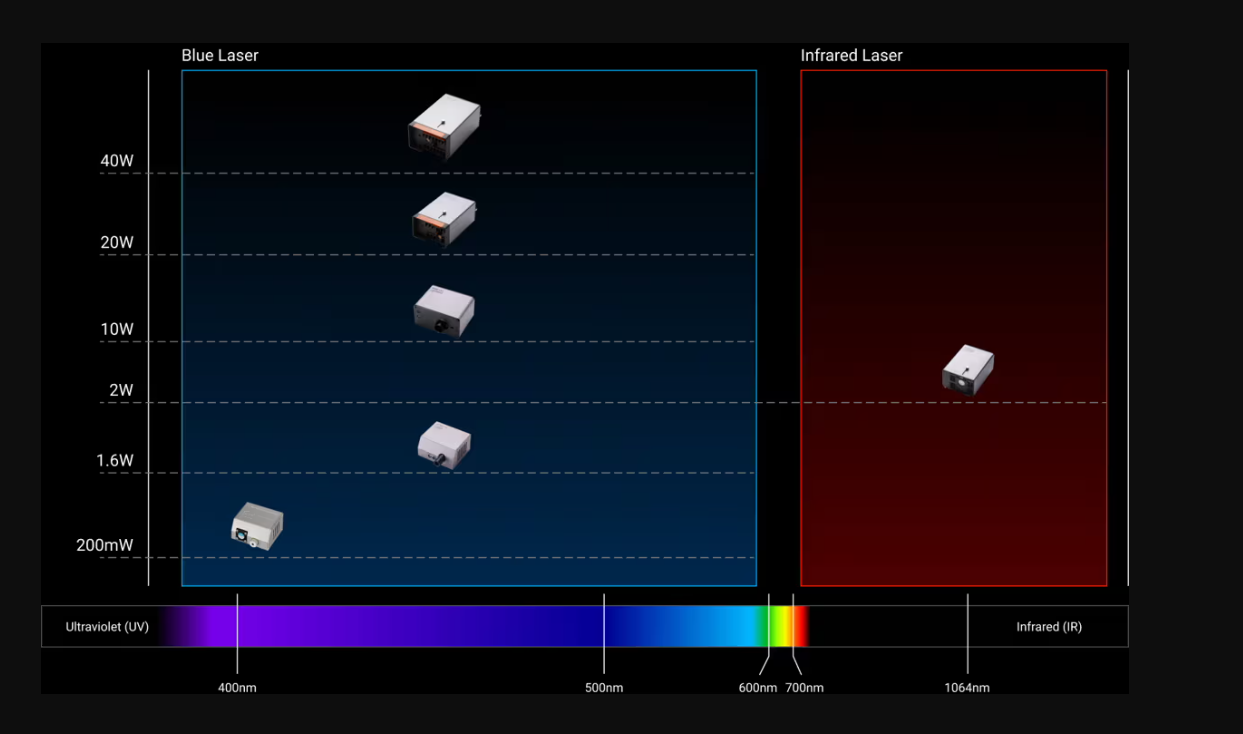

The Science Behind Laser Wavelengths

- Blue Lasers: Operate at wavelengths around 440–450 nm, which are in the visible light spectrum. Their shorter wavelength allows for higher precision and better absorption by various materials.

- Red Lasers: Function at wavelengths around 630–700 nm. These longer wavelengths are also visible but have less precision than blue lasers.

Why Choose a Blue Laser for Engraving and Cutting?

- Precision & Detail: Smaller wavelengths translate into sharply engraved blue lasers, tightly intended lines, and reduced diffusion on reflective surfaces.

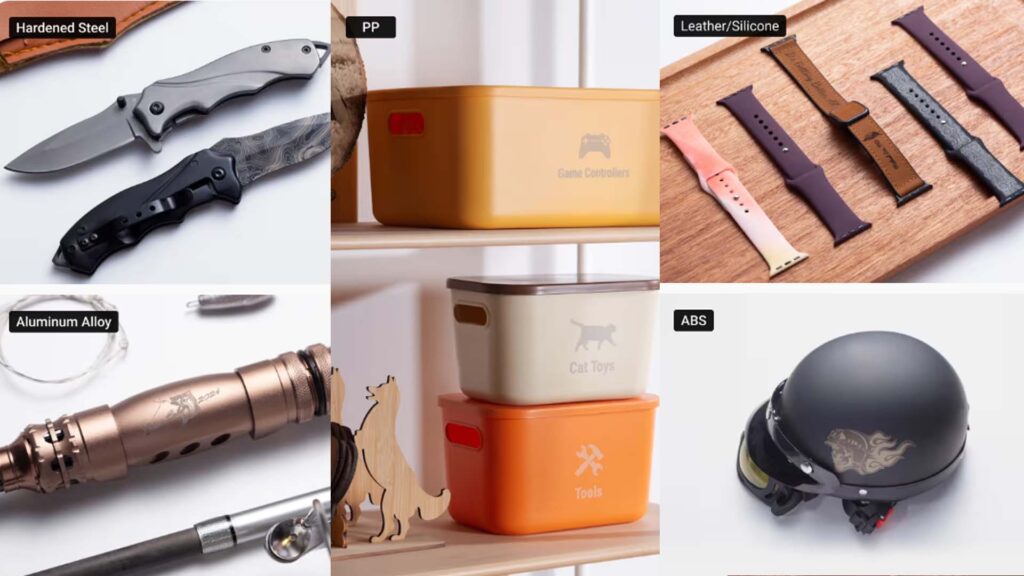

- Material Compatibility: They perform exceptionally well on wood, metals, and shiny surfaces, as these materials absorb blue laser light more effectively.

- Energy Efficiency: Blue lasers offer higher energy levels and intensity, making them efficient for demanding tasks.

- Related Term: Blue laser engraving excels in delivering intricate and precise results.

When a Red Laser Might Be Your Best Bet

- Versatility & Cost-Effectiveness: Red laser diodes are widely available and are typically more affordable.

- Simplicity in Most Situations: Performs reliably on matte, non-reflective surfaces, making it suitable for general-purpose applications.

Application Scenarios: Blue vs Red

The choice between blue laser vs red laser depends on the materials, precision requirements, and budget considerations.

Engraving & Cutting

Blue lasers excel at intricate engraving on various materials, including tough or reflective ones. Red lasers handle basic cutting and engraving at a lower cost but with less refinement.

Measurement & Alignment

Red lasers are commonly used in sensors and industrial measurement tools due to their availability and speed. Blue lasers can offer higher accuracy in specialized scenarios but at a higher cost.

Handling Reflective, Organic, and High-Temperature Surfaces

Blue lasers maintain focus and precision on shiny surfaces, hot metals, and translucent materials. Red lasers struggle with these conditions due to deeper penetration and diffusion.

Cost and Efficiency Considerations

Red lasers are generally cheaper to produce. Blue lasers may cost more upfront, but they can offer long-term energy savings.

Operating Safely with Red and Blue Lasers

Both types of laser are visible, which enhances safe handling. Always follow these safety measures:

- Use proper protective eyewear.

- Follow manufacturer guidelines.

- Ensure adequate ventilation and workspace precautions.

Blue Laser Modules Recommendation

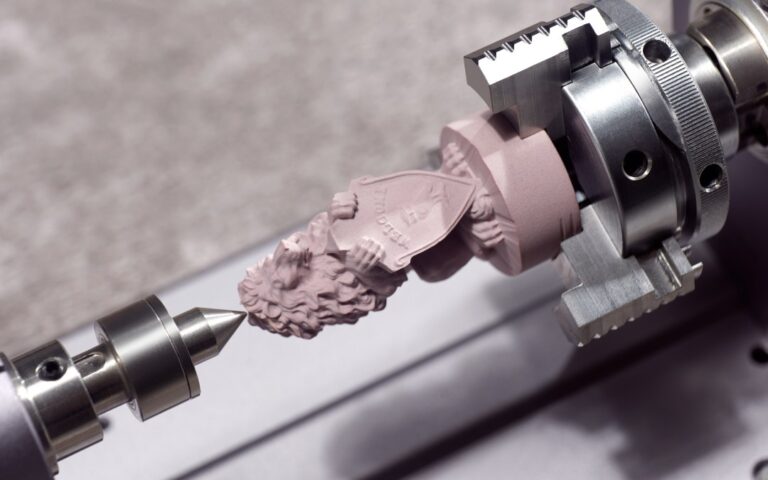

If you are looking for the best blue laser module, consider Snapmaker laser modules. The Snapmaker 10W High Power Laser Module features advanced laser beam splitters, doubling the power from 5W to 10W. It works at speeds up to 6000 mm/min and can cut through 8 mm basswood, making it eight times faster than the 1.6W module—perfect for efficiently tackling more materials and projects.

The Snapmaker 20W & 40W Laser Module with Air Assist offers powerful cutting capabilities, handling up to 20mm pinewood or 15mm basswood plywood in a single pass (40W) and 10mm basswood plywood (20W). Its smart Air Assist reduces charring, enhances quality, and keeps the laser lens clean and controllable via Luban for seamless operation. Enjoy 1000+ ready-to-use design templates in Luban for quick and creative projects.

Other Types of Laser: Infrared

So now we know that blue lasers are great for deeper engravings and cuts, and red lasers are perfect for matte, non-reflective surfaces. However, another type of laser is very popular: infrared lasers.

Infrared lasers emit invisible light at the typical wavelength of 1064 nm, so special safety measures are needed. Infrared lasers have a smaller laser spot, perfect for delicate engraving and detailed designs. Click here for detailed information about infrared lasers.

The Snapmaker 1064nm Infrared Laser Module engraves plastics and metals with precision, integrating seamlessly with Snapmaker 2.0, Artisan, and Ray series. Its built-in safety sensor halts operation if misaligned, while the AB position feature in Luban ensures flawless graphic placement for efficient engraving.

The Final Verdict: Blue Laser vs Red Laser

Blue and red lasers each have their strengths and limitations. Blue lasers are outstanding in energy efficiency: no other laser takes the performance efficiency match; it can be applied to a broader range of materials than red lasers can. Red lasers, however, win on price and speed for all-round applications. It’s essential to match your laser choice with project requirements. You should also consider material type, precision needs, and budget.

With a clear understanding of these differences, you can confidently select the laser that best suits your needs.