Make It Happen | Snapmaker 5th Anniversary Message From the CEO

Snapmaker is turning 5 years old! Our CEO Daniel Chen reflects on our journey with our supportive users and partners and look to the future.

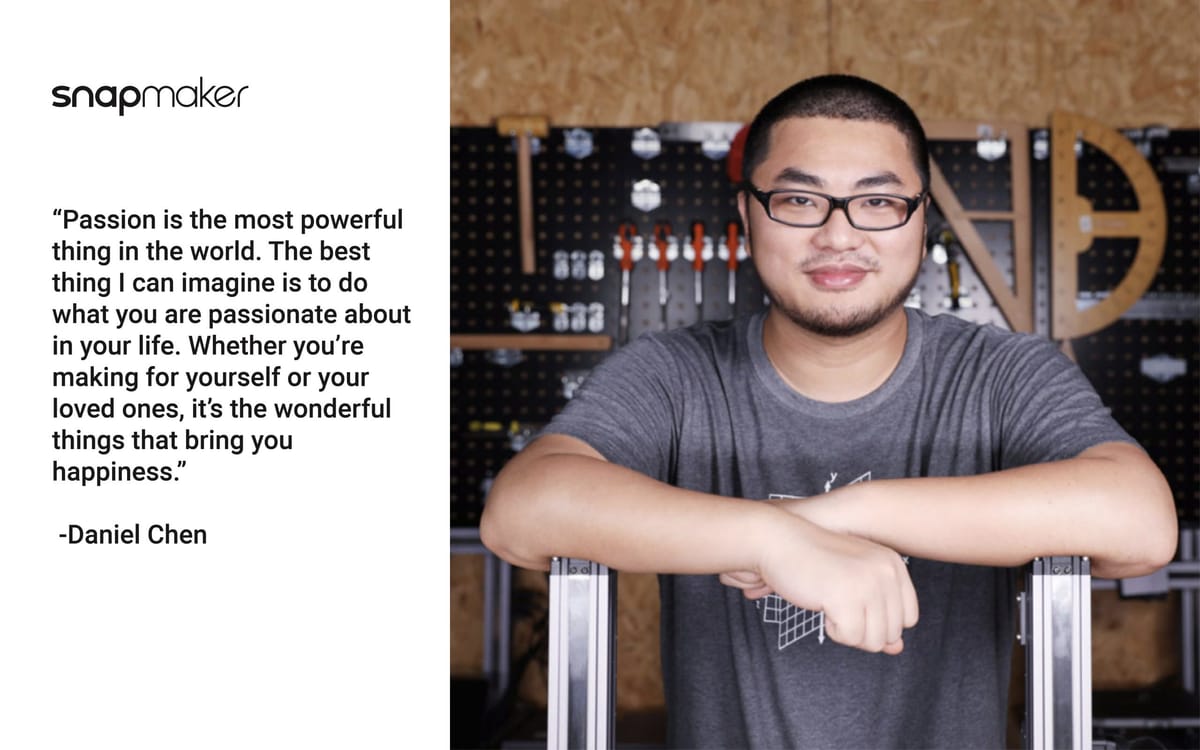

"Passion is the most powerful thing in the world. The best thing I can imagine is to do what you are passionate about in your life. Whether you're making for yourself or your loved ones, it's the wonderful things that bring you happiness."

Snapmaker's story began on June 1, International Children's Day of 2016 when I quit my job as an engineer. I chose this special day as a reminder to always be curious and follow my heart.

It all started at a Makerspace with 3 engineers, and 1 operation staff where we developed and knuckled down on Snapmaker Original and the Kickstarter campaign. Fortunately, the product made its successful debut on Kickstarter in March 2017. Two years later, Snapmaker 2.0 raised 7.85 million dollars as the most funded technology project in Kickstarter's history. In March 2021, we raised millions in series A funding. We couldn't have made it without the trust and support from our backers and users.

The past five years have witnessed the joint growth of the Snapmaker team, our users, and partners. We're grateful to have an online community of over 150k followers and members; We've developed our own business model with a combination of crowdfunding, direct selling, and distribution, with over 60,000 machines shipped to more than 120 countries and welcomed by makers, hobbyists, educational organizations, and small business owners.

Our team has also grown from 4 to over 200 and every one of us shares a set of values: Innovation, Rigorousness, and Diligence.

Being innovative means always creating values for our consumers with good products. We made the all-metal 3-in-1 3D printer, as all-metal represents ultra-precision, premium quality, and high standard, whereas the 3-in-1 modular design makes a highly expandable modular platform that is fun to play with, and 3D printing is the path we have chosen.

Being rigorous is to be perfectionistic about the quality of our products. Being a user-oriented company, we've been committed to maintaining high product quality and pursuing perfection.

Being diligent means pushing the limits to perfect our hardware, firmware, software, and supply chains to deliver a satisfying user experience. In July 2017, we established our first production line to accommodate the production and assembly of Snapmaker Original. In 2020, we built a new factory and extended our production capacity to 5,000 units per month in 6 months.

Our brand concept has shifted from "Make Anything" to "Make Something Wonderful" over the years. In the beginning, we hope to empower every user with the ability to make anything. However, life is short, and we only have limited time and energy to focus on what we're passionate about.

"Make It Happen" is the theme of our 5th anniversary, which also reflects what we think about making. Wonder doesn't just happen by coincidence, it belongs to those who dare to dream and take action. From what I've seen every Snapmaker user is a wonder maker.

Our mission is to "create excellent tools to empower creation". Next up, we will continue making tools accessible to regular consumers with engineering technology, to empower each individual to enjoy making, and make something wonderful.

Daniel Chen

Snapmaker CEO