Guide to FDM 3D Printer Maintenance

FDM 3D printing is a quite common 3D printing technology that builds objects layer by layer by extruding melted material through a filament. Like any other printer, a 3D printer also experiences wear and tear and breakdown if it’s been in operation for ages. Ensuring its maintenance on time helps extend your printer’s life and results in smooth prints.

In this guide, we will provide you with an overview of everything you need to know about 3D printer maintenance, thereby assisting you in putting your 3D printer into service and saving it from breakdowns. It also covers cleaning the physical components of your printer, including how often to clean 3D printer nozzle, and how often should I level my 3D printer and keep them in perfect condition.

What Maintenance Is Required for a 3D Printer

3D printer maintenance is essential for ensuring consistent quality and extending your printer’s longevity. Let’s analyze each type of maintenance in detail in the following 3d printer maintenance checklist.

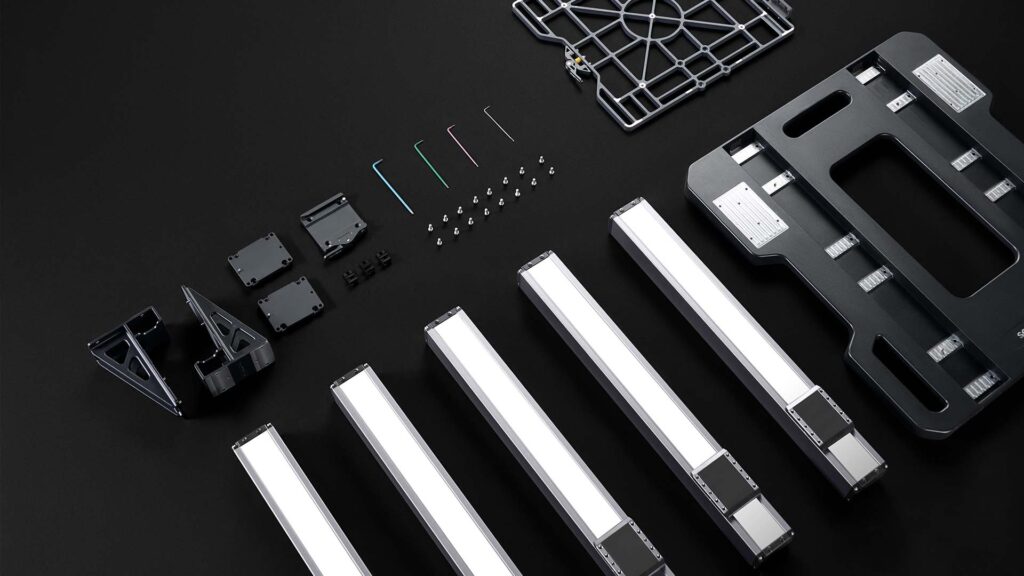

Mechanical System Maintenance

- Moving parts lubrication: Reducing friction and wear, achieving smooth function.

- Steel strip of the linear module: Remove accumulated tar buildup, which can be flammable and impair lubrication.

- Linear rail and bearing care: Clean to keep from binding and lubricate for precise motion.

- Structural integrity checks: Ensure all components are well-positioned.

Thermal System Maintenance

- Hot end cleaning: Less filament residue, less potential clogs.

- Nozzle replacement and care: Worn or clogged nozzles result in poor print quality.

- Heating element performance monitoring: A properly functioning heating element helps maintain the correct printing temperature.

- Thermal interface management: Proper thermal paste application ensures efficient heat transfer between the heating block and heat sink.

Electronic System Maintenance

- Electrical connection checks: Be free from safety hazards.

- Firmware updates: Optimize the experience through bug fixes and new features.

- Control board health: Monitoring for signs of damage or overheating.

- Cooling system maintenance: Ensure fans are working correctly.

Related guides: 3D Printer Fire Safety – Causes, Prevention, and Best Practices

Consumables Management

- Filament storage: Proper storage prevents moisture absorption and ensures consistent extrusion.

- Build plate care: A clean and prepared build plate ensures good print adhesion.

Daily Maintenance Essentials

- Post-Print Clean-Up: Clean the build plate and remove print remnants. Tools for effective cleaning may include a scraper (for stubborn parts), a brush (for loose debris), and a microfiber cloth (for wiping the surface).

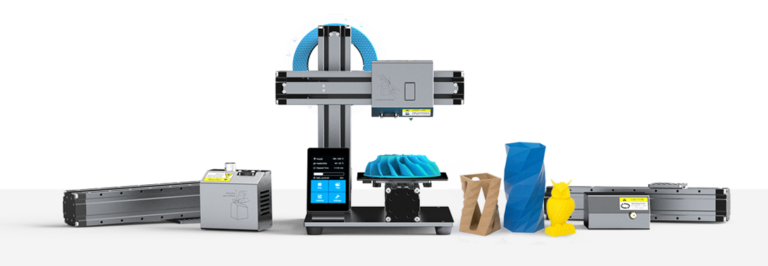

- Filament Storage: Place filaments in cool, dry places and airtight containers. Using desiccants like silica gel packs can actively absorb moisture. Identifying Signs of moisture-damaged filament, such as increased brittleness, a rough surface finish on prints, or audible popping or hissing during extrusion, indicates the need to dry the filament. Snapmaker presents the SnapDryer, a device that merges drying and storage functionalities.

Related guides: How to Clean Your 3D Printer Bed ; How to Store and Dry 3D Printer Filaments

Weekly Maintenance Checklist

- Steel strip inspection and cleaning: Clean by first removing the linear module, wiping the steel strip with a cloth soaked in alcohol, applying lubricating oil to the cleaned surface, and finally reinstalling the module.

- Linear rail and bearing lubrication: Apply a few drops of light machine oil or a suitable bearing grease along the length of the rails, moving the print head/bed to distribute it. Wipe away any excess.

- Checking for loose screws and connections: Pay particular attention to screws around motors, the hot end, and the frame. Gently tighten any that have come loose – avoid overtightening.

- Watch for frayed belts or worn bearings. Listen for unusual noises from bearings during movement, which could indicate wear.

- Cleaning methods for nozzles include cold pulls or using cleaning filaments/needles.

- Flattened tips or inconsistent extrusion could be signs of nozzle wear.

Monthly Deep Maintenance

- Bed leveling procedures: Perform manual leveling using paper or your printer’s automatic bed leveling (ABL) feature.

- Z-axis calibration for proper first layer adhesion and overall print accuracy.

- Measure and adjust the extrusion multiplier in your slicer software to ensure the printer extrudes the correct filament amount.

- Clean dust from the cooling fan blades. Dust can impede airflow and reduce cooling efficiency.

- Regularly check the manufacturer’s website for firmware updates. Read the release notes to understand the changes. Follow the update instructions carefully to avoid bricking your printer.

Long-Term 3D Printer Care

- Tracking maintenance helps identify patterns and predict future needs.

- What to track: Log dates, tasks performed, and any issues encountered.

- Ideal printer placement: Choose a stable, level surface away from drafts and direct sunlight, which can cause temperature fluctuations.

- Dust and debris prevention: Use covers or keep the printing area clean.

Final Words

Maintenance of your 3D printer is extremely vital to producing good quality, long-lasting products that you can use. You should be inspecting your 3D printer very often if you are using it regularly for any other applications and checking for wear and tear. Now, maintenance keeps the printer working for long periods and helps you maintain a high-quality print forever.