How to 3D Print Multiple Colors: 3 Main Methods

3D printing can make your business soar in a matter of months. It makes the manufacturing process more efficient and is great for prototyping products that will help you reach the market faster.

Whether it’s fashion, furniture, architecture models, automotive spare parts, medical implants, or just to channel your creativity, 3D printed models are the best way to make your ideas come alive.

Want to learn more about 3D printing? Keep reading to find out!

Why Print in Multiple Colors?

Multiple-color 3D printing is a sustainable process that leaves minimal waste while allowing you to make detailed products quickly. The fact that it has become cheaper than before, allowing manufacturers to make higher quality products with relative ease, has made 3D printers more accessible to private organizations and businesses.

Suppose you are manufacturing prototypes for your product, whether architecture or consumer-centric. In that case, it gives them a more authentic feel and allows investors to see the potential in your business. Besides that, you have more control over the end product, where you can add details or remove features on the soft form of your design in the CAD software before transferring it to CAM software.

Multiple-color 3D printing can change the game for you once you get the hang of it. Since you can do 3D printing in multiple ways, you can choose whichever is most convenient for you and make the most of your products.

Method 1: Printing Single-Color Components and Assembling Them

One of the ways you can 3D print in multiple colors is by using a single color extruder to create the components of the same color, by separating STL files and arranging the components afterward to assemble your end product.

To join the different components, you can use super glue, hot guns, epoxy, or any other bonding material to fasten the pieces together.

It’s quite a straightforward and budget-friendly option for 3D printing in multiple colors, but it is more time-consuming since you’ll need to take the time to assemble your products.

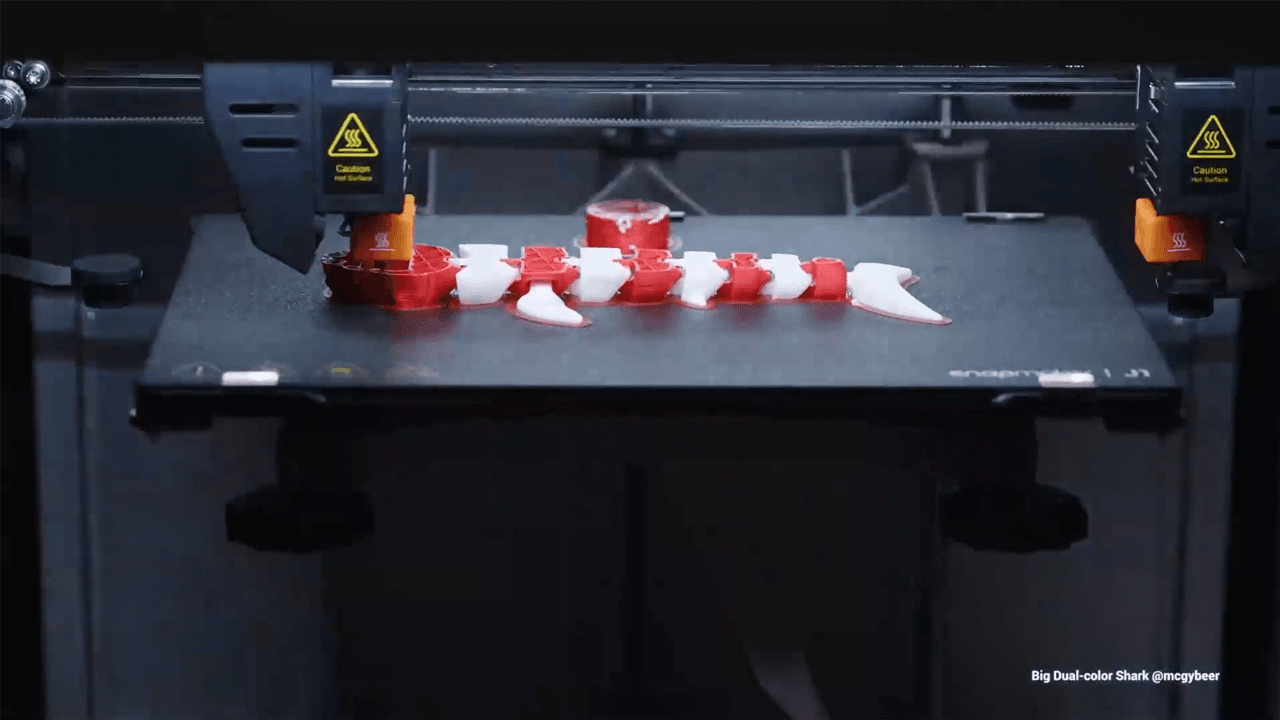

Method 2: Using Dual Extruder 3D Printers

Snapmaker J1S is an excellent choice for dual extruders for multiple-color 3D printing, thanks to its IDEX technology that allows the dual extruders to print simultaneously and independently.

Snapmaker Artisan takes it one step further, integrating 3D printing, CNC, and laser cutting all in one machine, allowing you to make the most of your 3D printer.

After designing your model, assign each part to different extruders, configure the settings according to the filament, and use the slicer to generate the G-code, allowing the extruders to switch at appropriate times.

Although this may be a bit more costly than the assembling method, it yields better results while making the process more efficient.

Related reading: What is a Dual Extruder 3D Printer? The Possibilities and Limitations

Method 3: Using Multicolor Filaments

Multicolor filaments are an efficient way to achieve multicolor 3D printing, but their precision depends on the specific printing method and filament type. Single-nozzle printers using multicolor filaments can streamline the process, but the color transitions may appear blurred or imprecise. On the other hand, multi-nozzle printers offer greater control over color placement, making them ideal for designs that require high precision.

Multicolor filaments are particularly suitable for creating creative effects like gradients, rainbows, or glow-in-the-dark designs. However, these effects require careful planning and advanced slicer settings to ensure the final product meets expectations. Designers should be prepared to experiment to achieve the best results.

Factors to Consider Before Printing Multiple Colors

Multicolor 3D printing is a step up from sculpting models in one color, but there are a few factors you need to consider beforehand.

Is Your Printer Ready for Multicolor 3D Printing?

Whether or not you are ready for 3D multicolor 3D printing depends on your printer. Some printers are more suited to multicolor 3D printing than others, depending on the type of product you are creating as well as the technique you are accustomed to.

Using a 3D printer with a single extruder and assembling them afterward might be easier for some people than using a multicolor filament or double extruder that combines colors and printers in one print.

You also need to ensure your CAD and CAM software are up to date to ensure the precise development of your product.

Materials for Multicolor 3D Prints

You also need to pay attention to the materials you will use for 3D printing. PLA is a good option, along with ABS or PETG, which are more durable but require more experienced designers and advanced settings.

The type of product you create will also determine the materials you need to use, so make sure you plan it out carefully.

Calibrating Your 3D Printer for Multicolor Success

3D printing in multicolor requires precision, especially in dual extruder printers, which start with proper calibration. This means ensuring the extruder’s accurate setting concerning the filament’s amount and temperature. X, Y, and Z axes must also be measured to ensure the printer is assembled correctly. At the same time, routine maintenance of the extruders allows them to do their job correctly, which prevents unnecessary bleeding of nozzles or irregular smudges.

Considering all these factors will save you time and losses that come with 3D printing, resulting in professional-looking products that will surely make investors and customers swoon.

Bring Your 3D Creations to Life with Colorful Innovation.

Multiple-color 3D printing is a sure way to upgrade your products and channel your creativity by bringing your ideas to life.

It doesn’t matter what printing method you choose. Whether printing with a single extruder and assembling afterward, using a double extruder to switch between two colors, or using a multicolor filament printer to print simultaneously, each one will be a worthy companion in your creating process.

If you want to take your products to the next step, Snapmaker 3D printers will make a great choice, producing great results in less time.

So, ready to create vibrant 3D prints? Start with these techniques and bring your ideas to life!

FAQs About Multi-Color 3D Printing

Yes, it is possible to print multiple colors with a single extruder by manually swapping filaments at specific points during the print or using multi-color filaments. This method requires careful planning in your slicing software and may involve pausing the print to change colors.

Dual extruder printers, like the Snapmaker J1S or Snapmaker Artisan combain with Dual Extrusion 3D Printing Module, are among the best options for multi-color 3D printing. These printers allow seamless transitions between colors and are highly versatile for multi-material prints.

Yes, multi-color filaments can be used with both single and dual extruder printers. However, in dual extruder setups, you gain more control by assigning specific filaments to each extruder, allowing for more complex designs.

Ensure proper printer calibration, especially for dual extruder models to prevent color bleeding. Regularly clean the nozzles and use high-quality filaments to minimize blending or smudging during the print.

Slicing software like Cura, PrusaSlicer, or Simplify3D is essential for preparing multi-color prints. These programs allow you to assign colors to different sections or layers and preview the final output before printing.

Multi-color printing can be slightly more expensive due to the need for additional filaments or dual extruder setups. However, the added cost is often worth it for the improved aesthetic and functional results.

Many modern 3D printers with dual extruders or filament sensor systems can switch colors automatically during printing. However, single extruder printers require manual intervention to change colors mid-print.