How to Make Money with a 3D Printer

Want to make money with a 3D printer? It’s totally possible—but it takes more than just hitting “print.” From choosing the right niche to pricing, marketing, and workflow, this guide walks you through how to turn your printer into a profitable business. Let’s turn layers into income.

Table of Contents

Can You Make Money with a 3D Printer?

Absolutely—but it’s not automatic. A 3D printer can be a right tool for making money, but success depends more on how you use it than the machine itself. Many of us overlook the value of skills like 3D modeling, creativity, and an acute sense for what people actually want to buy.. That said, even beginners can start earning by offering print services or customizing existing designs. It’s not just about printing stuff—it’s about solving problems in cool ways.

Or you can sell 3D printers, go big and develop cutting-edge 3D printers like Snapmaker does.

Either way, if you’re curious about real ways to turn your printer into profit, check out our blog on 3D Printing Business Ideas.

How to Make Money with a 3D Printer: A Startup Guide

1. Choose Your Focus (Niche is Key)

Start by defining what kind of 3D printing business you want:

- Product-based: Custom prints, home tools, cosplay, decor, etc.

- Service-based: Print-on-demand, prototyping, replacement parts.

- Digital goods: Designing and selling STL files.

- Content & education: Tutorials, time-lapses, or teaching others.

Tip: Pick something you’re personally interested in—it makes marketing and iteration easier.

2. Validate Your Idea

Before investing too much:

- Test your product idea with small batches.

- Join online groups (Reddit, Facebook, Discord) to gather feedback.

- Check similar products on Etsy, eBay, or niche shops—see what sells and at what price.

- Even useful, everyday prints can be winners. Think practical first, fancy later.

3. Set Up Your Tools & Workflow

You don’t need a lab. You need:

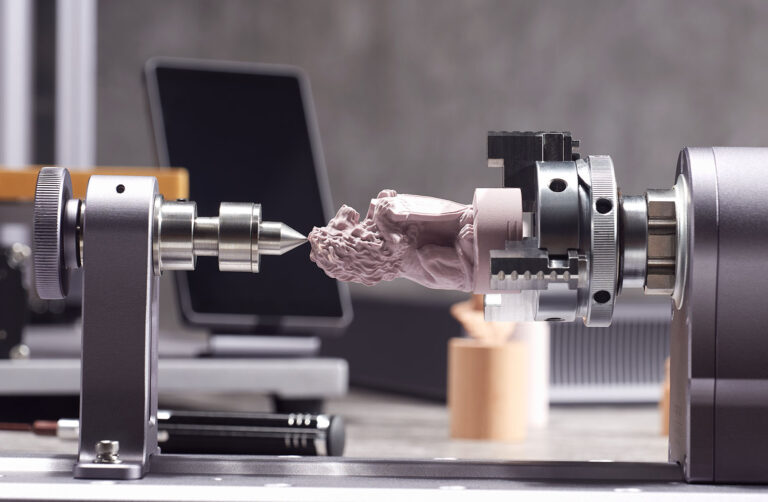

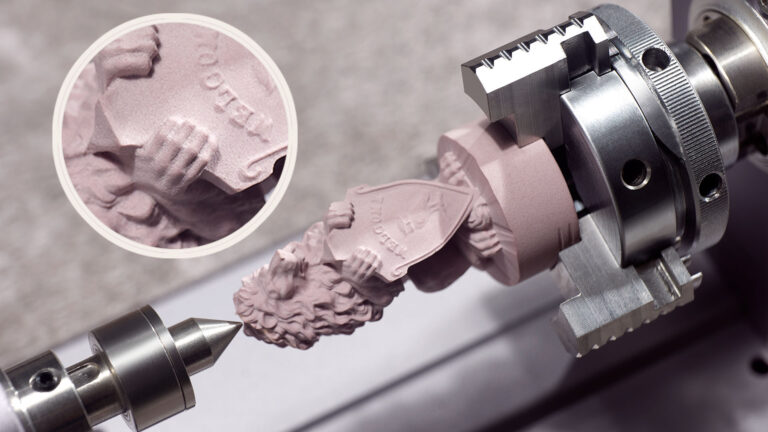

- A solid 3D printer (FDM or resin depending on your niche).

- Slicer software (e.g. Cura, PrusaSlicer).

- Modeling tools (Tinkercad, Blender, Fusion 360).

- Post-processing gear: sandpaper, resin cleaners, spray paint, etc.

Start small and dial in your workflow and workshop. Consistency > volume at the beginning.

4. Price Your Work Thoughtfully

Don’t just guess—build your pricing with care:

Start with your total cost:

- Filament/resin

- Electricity

- Machine wear

- Failure risk (especially for big prints)

- Post-processing time

- Packaging and shipping

- Ad spend (Etsy Ads, Meta Ads, etc.)

Then apply a multiplier:

- 2x–3x for hobby/side hustle

- 4x–5x if this is your full-time business

Optional risk buffer:

For large or complex prints, add a time-based charge, like $0.25/hour, to cover failure risk.

Adjust by complexity:

- A simple box? Lower rate.

- Complex supports, delicate finishing, or custom design? Price it higher.

Tip: Check the market to make sure you’re not over- or under-charging.

5. Build Your Brand & Online Presence

Look professional—even if you’re starting from your garage.

- Create a name, logo, and simple visual identity.

- Build a basic site or use Etsy/Gumroad to sell.

- Be active on social: show WIPs, time-lapses, packaging, and customer stories.

Tip: People love watching the process—use that to your advantage.

6. Marketing: Invest to Grow

Don’t wait for customers to find you—get in front of them:

- Use affordable paid ads (start small with $1–$5/day).

- Promote on social platforms and niche forums.

- Partner with influencers or do small giveaways to build trust.

Tip: Smart marketing helps stabilize your income—and builds your brand in the long term.

7. Start Selling and Refine

- Offer a few core products or services at first.

- Get feedback early and often.

- Handle shipping with care—quality packaging matters.

- Use automation tools (e.g., for digital STL delivery or Etsy auto-replies).

Tip: Stay flexible. You’ll learn what sells, what doesn’t, and what you enjoy doing.

8. Keep Leveling Up

- Improve your modeling skills—unique designs unlock higher margins.

- Watch market trends and adapt fast.

- Upgrade gear only when the extra value is clear.

- Build a following—people buy from people, not just shops.

Important Considerations

Legal and Regulatory Issues

Be aware of prohibited items. Many platforms (including Facebook Marketplace, Etsy, etc.) strictly prohibit weapon-related 3D prints. Even discussing such prints can get your account banned. The best approach is to avoid these requests completely and block users who ask for such items.

Intellectual Property Rights

Consider whether you’re selling print time or finished products:

- Selling print time only: The customer provides the model and takes responsibility for IP rights

- Selling finished products: You need proper licensing for any copyrighted designs

- Creating original designs: Gives you the most control but requires design skills

Most print-on-demand services will reject unauthorized IP, as they share liability for infringement.

The Bottom Line: Business Setup Checklist

- Define your niche and validate market demand

- Set up optimal workspace with necessary equipment

- Create pricing structure that ensures profitability

- Establish online presence across relevant platforms

- Implement marketing strategy to reach target audience

- Develop fulfillment process for consistent quality

- Plan for continuous improvement and skill development

- Understand legal boundaries regarding IP and prohibited items

- Track expenses and income for tax purposes

- Join communities for networking and staying current with trends

Ready to start? Focus on delivering value, and let your printer become your partner in building a profitable venture.