Laser Engraving Materials: Choosing the Right One for Your Project

Laser engraving is one of the most popular forms of art today. Not only does it give unmatchable quality, but it is also quite flexible in the products you want to conceive.

Whether it’s wood, plastic, metal, glass, or leather, laser engraving machines deliver. Want the ultimate logo for your brand or the best gift for your buddy? Laser engraving will provide a quick save.

However, the choice of material matters a lot in the type of product you are going for since the process and the result are going to differ for each one.

Wood

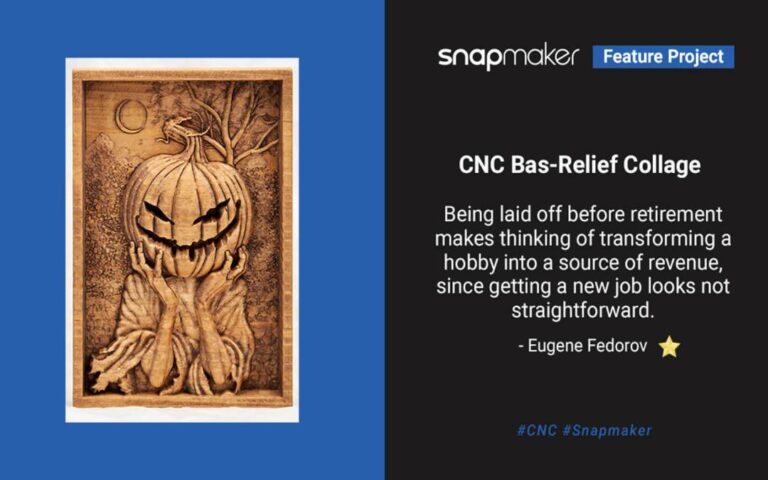

Wood is quite an easy material to work with for laser engraving. The method comes as one of the leading choices among woodworkers due to its ease, where you can create the most organic prototypes, photo-engravings, inlays, and decoration pieces in a matter of seconds.

You also need to take care of the type of wood you choose, considering the kind of product you are working on. If it’s a high-end product, maple, cherry, and walnut wood provide the best quality, but plywood and MDF are wiser choices if they are large-scale production.

Acrylic

You can create the most versatile products with laser engraving on acrylic. The layers in the material allow room for different textures, like frosting or a multicolor effect, while giving precise results on the exterior with clean cuts and sharp edges perfect for creating awards and decorative items.

The properties of acrylic align perfectly with the laser engraving method, giving you a consistent set of results each time that you can actively rely on.

Leather

Leather goods make major use of laser engraving methods for personalized gifts with patches and adding details on bags and wallets. Both vegetable-tanned and natural leather make good options for engraving. However, you should avoid synthetic leather if you want to maintain quality and ensure the safety of you and your machine.

Metals

Laser engraving works on almost all materials, including metals. It’s especially effective on Aluminum 6061 and Brass H62, creating long-lasting, durable designs. Aluminum 6061 is a popular alloy known for being strong, lightweight, and resistant to corrosion, making it ideal for various applications. Brass H62, conversely, is a high-quality brass alloy composed of copper and zinc. Its golden hue and excellent malleability make it a great choice for engraving intricate details.

Plastics

Plastics are usually the easiest material when it comes to laser engraving. Not only is it great for marking but also for sculpting, where you can mold the material into different shapes, allowing you to make cost-effective prototypes as well as customized gifts owing to its flexibility.

Avoid using PVC for laser engraving since it can result in toxic fumes and destroy the metallic components within your laser in just a few days. Acrylic is the best type of plastic you can use for your products due to its durability and versatility, allowing it to withstand the pressure of the method while yielding quality goods for your business.

Fabric and Paper

Laser engraving has opened a whole new dimension in the world of fashion. It has made designs more durable and strengthened fabrics by preventing fraying. No wonder it is one of the largest growing markets in the industry, where it works on different materials, including cotton and felt, to create varying textures like distressed and aesthetic vibes, extremely popular in today’s trends.

The same goes for paper, where the design is embossed onto the material rather than just laying on the surface, as the case is with printing, in which the design can seem superficial. Laser engraving on paper is also more precise and sustainable than printing, making it an excellent alternative for crafting custom packaging and invitations.

Factors to Consider When Choosing Laser Engraving Materials

Suppose you’re using a diode laser for engraving. In that case, materials like wood and leather are good choices since the wavelength of a semi-conductor is well-suited for these organic substances, allowing for precise and detailed engravings. For acrylic, while diode lasers can work, results might vary based on the specific type and color of the acrylic, so some experimentation might be necessary.

Metal is also extremely reflective during the process, so it’s best to wear safety goggles while ensuring the working area is well-ventilated for both kinds of material to prevent the build-up of toxic fumes.

Also, consider your budget before going for the material and the product you are manufacturing to avoid things getting out of hand.

Conclusion: Choose the Right Material

Laser engraving is a versatile method for designing and engraving on all kinds of material. It can work well with durable steel just as well as it can work it glass and paper.

All you need to make sure is that you have the settings under control and you are using the right kind of laser for the material.

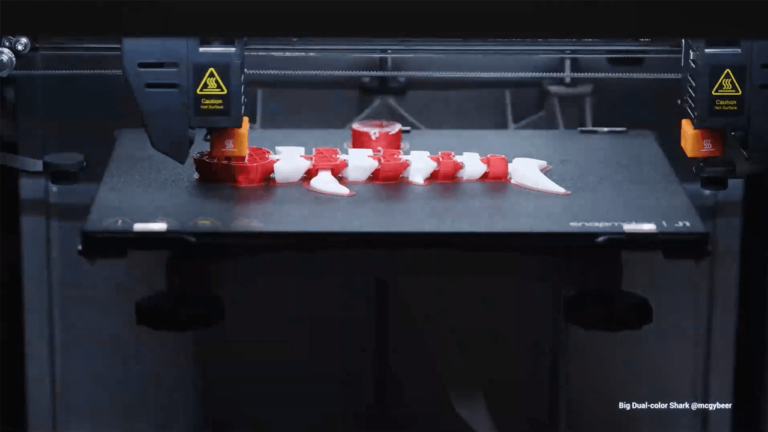

Choosing the right laser engraving material is just the first step—having a reliable engraver makes all the difference. With Snapmaker’s 3-in-1 3D printer and its powerful laser modules, you can engrave on dozens of materials effortlessly. Explore Snapmaker today and bring your creative ideas to life!