Can You Laser Engrave Metal?

Thinking about laser engraving metal? It’s a question we hear all the time, especially if you’re just starting out in the world of laser engraving. The answer is yes, absolutely! But, like with many things, the how and how well depend on the tools you use.

Join me as we explore the exciting world of laser engraving metal! We’ll discuss how various laser technologies, particularly diode lasers, are making metal marking more approachable and enjoyable than ever. Whether you’re a hobbyist, a small business owner, or a creative DIYer, diode lasers are a fantastic choice for bringing your metal projects to vibrant life!

Laser Engraving Metal: The Basics

When discussing laser engraving metal, it’s important to understand the key factors at play. Not all lasers are created equal, and their ability to work with metal varies based on a few crucial elements:

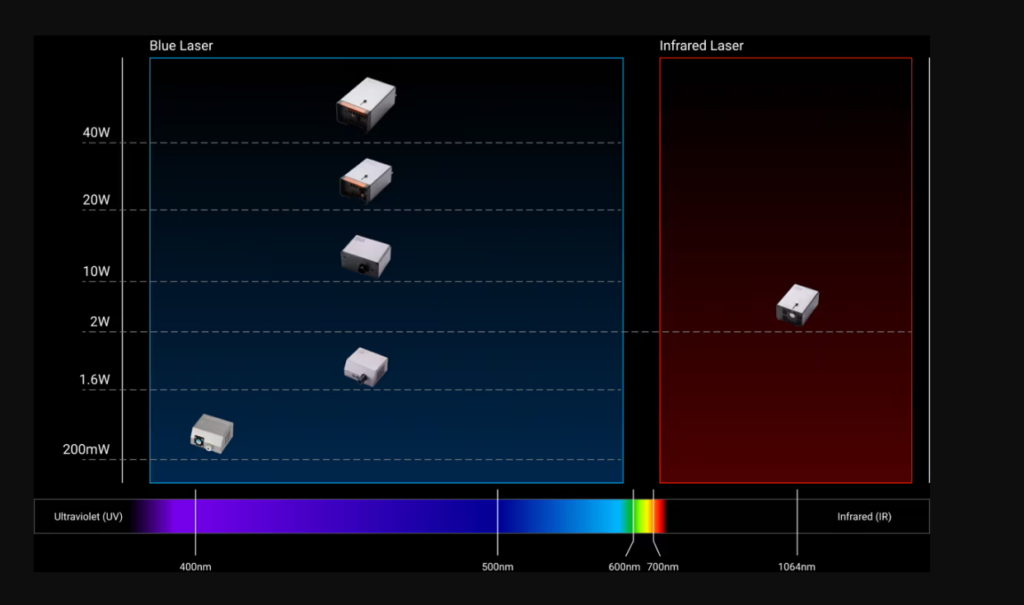

Laser Wavelength

Laser wavelength is key for metal engraving.

- Diode lasers (~450nm, blue light): Excellent for marked and coated metals

- Fiber lasers (~1064nm, near-infrared): Industrial standard for metal engraving

- CO2 lasers (~10,600nm, far-infrared): Less effective on bare metals

Metals generally absorb shorter wavelengths more effectively, which explains why fiber and diode lasers excel in metal applications. This absorption rate directly influences the marking quality and efficiency.

Metal Properties

Reflective metals like bare aluminum and stainless steel bounce laser energy away, making them challenging. Coated metals offer a solution because coatings can be designed to absorb laser energy more readily, improving marking potential, especially for diode lasers.

Surface Preparation

Coatings are crucial for diode lasers to mark metal. Metal marking sprays/pastes, like thermochromic types, are specifically formulated to absorb diode laser wavelengths.

How coatings enable diode lasers:

- Boost Absorption: Coatings readily absorb diode laser energy.

- Heat Transfer: Absorbed energy heats the coating, which transfers heat to the metal surface.

- Surface Reaction: Heat triggers a reaction (oxidation, etc.) on the metal, creating a visible mark.

- Surface Marking, Not Deep Engraving: Diode lasers with coatings primarily achieve surface marking, not deep material removal like fiber lasers.

Laser Etching vs. Engraving vs. Cutting on Metal

Laser Marking / Etching (Surface Level)

This is often what diode and CO2 lasers accomplish on metal surfaces, especially with coatings. It involves altering the metal’s surface appearance, creating:

- Color Change: The laser energy causes a chemical or thermal reaction on the surface, leading to a visible color change in the coating or the metal itself (oxidation in some cases).

- Slight Texture Change: The laser might subtly melt or vaporize the very top layer, resulting in a change in surface texture, often creating a matte or slightly raised effect.

Laser Engraving (Material Removal)

This is where powerful lasers like diode and fiber lasers take center stage. True laser engraving involves:

- Creating Depth: The laser removes a measurable amount of material from the metal surface, creating a physical indentation.

- Tactile Marks: The resulting mark is not just visual but also tactile – you can feel the engraving.

- Durability: Engravings are deeply embedded in the material, making them highly durable and resistant to wear.

Laser Cutting (Penetration)

For cutting completely through metal, you need significant laser power, primarily from Fiber lasers.

- Full Material Separation: The laser severs the metal, creating shapes and outlines.

- Not Typically Achieved by Diode Lasers: Consumer-grade diode lasers generally lack the power to cut through thicker metals.

Why Diode Laser Engravers Excel for Metal

While Fiber lasers are the champions of deep metal engraving and cutting, diode laser engravers carve out a valuable niche in metal marking, especially when you leverage their strengths effectively. Here’s why diode lasers are an excellent choice for many metal projects:

- Affordability: Diode lasers are much cheaper than Fiber or CO2 systems, making metal marking accessible to hobbyists, small businesses, and DIY enthusiasts.

- Versatility: Diode lasers aren’t just limited to metal marking. They can handle a wide range of other materials like wood, acrylic, leather, paper, fabric, and more. This multi-functionality makes them a fantastic all-in-one tool for creators who work with diverse materials.

- Ease of Use: Compared to complex industrial laser machines, diode lasers are relatively simple to learn and operate, making them ideal for beginners and those who value ease of use.

- The Key Limitation & The Smart Solution: It’s true that diode lasers aren’t designed to directly engrave bare, reflective metals deeply. However, using coatings like thermochromic spray allows the surface to absorb diode laser energy, enabling beautiful, permanent markings on coated metals.

Creative Applications of Diode Lasers on Metal

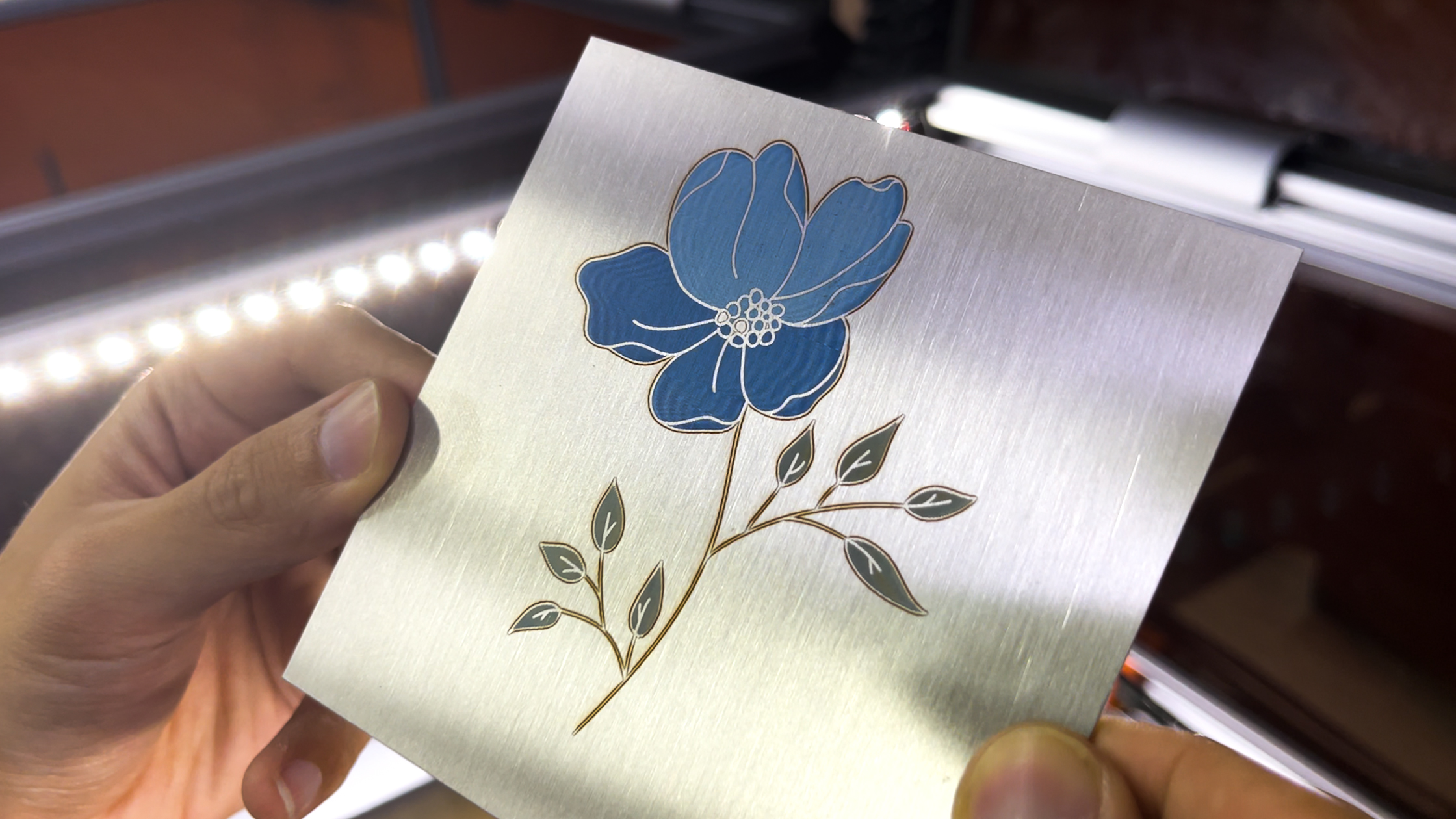

Diode lasers, when paired with smart techniques, open up exciting creative possibilities for metal marking:

- Personalized Gifts: Create custom dog tags, keychains, and metal business cards with names, dates, or special messages on coated metals or anodized aluminum.

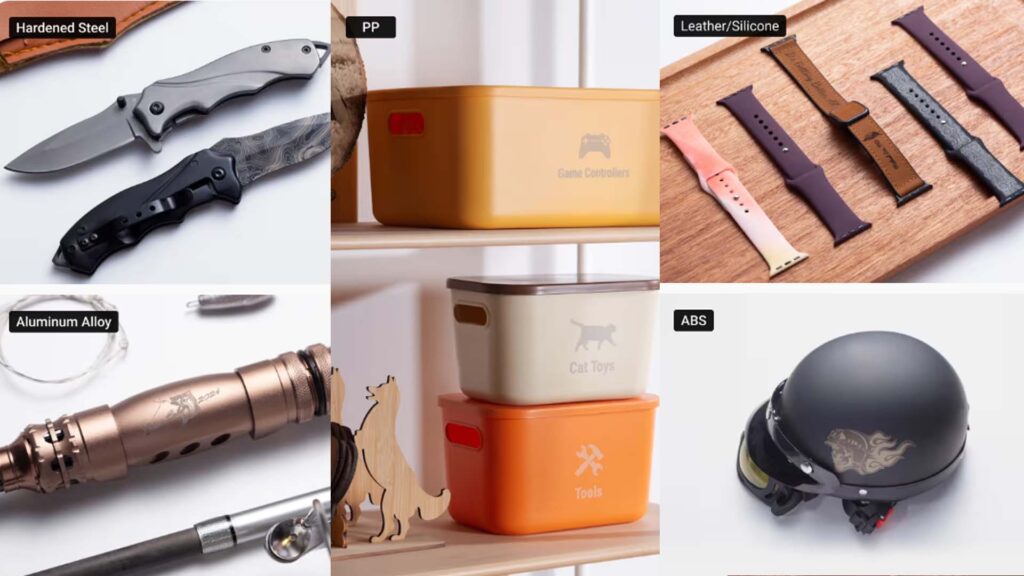

- Industrial Part Labeling: Add serial numbers, QR codes, and logos to powder-coated or painted metal parts for identification and branding.

- Art and Décor: Design unique engraved metal signs, ornaments, and jewelry pieces using coated metal blanks and your diode laser’s precision.

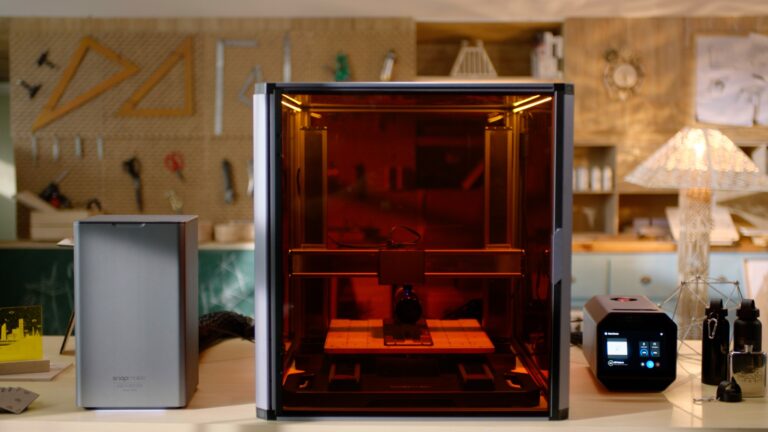

If you’re a multitasking maker, Snapmaker Artisan is highly recommended for its versatility and flexible setup. Artisan isn’t just a laser engraver—it’s a 3D printer, CNC carver, and laser engraver in one. You can switch from engraving to 3D printing or CNC carving in minutes for metal engraving, prototyping, and custom fabrication.

What if you want to engrave bare metals like stainless steel, copper, or titanium without sprays or coatings? In this case, the Artisan machine’s real magic for metal comes into play. Its compatibility with the 1064nm Infrared Laser Module allows for direct interaction with these metals—eliminating the need for any coatings. Here is the latest list of the supported metals:

- Common Metals: Stainless steel, aluminum, copper, titanium.

- Precious Metals: Gold, silver.

- Industrial Materials: SPTE (steel plate), tinplate, painted metals.

Conclusion

Can you laser engrave metal? Yes! Diode lasers are an excellent and accessible choice for metal marking. While not meant for heavy-duty cutting or deep engraving of bare metals (that’s where Fiber lasers shine), diode lasers allow creators to achieve impressive results on coated metals and anodized aluminum.

Explore Snapmaker’s Artisan and Infrared Laser Module! These professional-grade tools enable you to work smarter—and bolder—on metals.

Always prioritize safety and follow guidelines when using laser engravers.