Laser Engraving vs. Etching: What's the Difference?

Laser technology has redefined precision and creativity in marking processes. Laser engraving and etching are high-tech methods used for very fine details, but they serve different purposes or applications. Knowing how these differ will help you make an informed decision about which one to use for your needs.

Thus, this blog decodes the differences between laser engraving vs laser etching, as well as the respective laser marking methods to help you choose a suitable technique for your project:

How Laser Engraving Works

High-energy laser beams are concentrated on the surface of a material to create extreme heat, melt, and vaporize it. These beams create a clearly defined cavity, which forms a very deep and long-lasting mark that may be viewed with the naked eye. The beam releases excessive energy throughout the process and acts like a chisel to create deep and permanent designs.

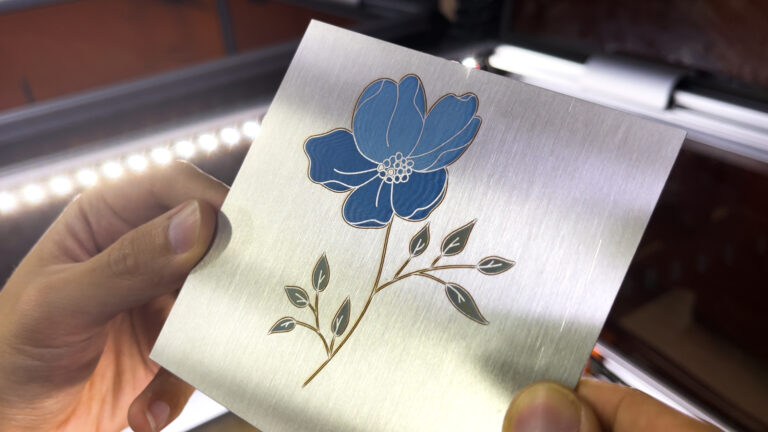

Among the most relevant materials for the application of laser engraving are metals, wood, glass, leather, stainless steel, and the like. The laser engraving technique is often used for products vulnerable to wear and tear, thus the remarkable variety of applications in branding, various industries, and making custom-made products.

How Laser Etching Works

Laser etching is nothing but laser engraving. It is done by energizing the beam with added pulse-shorts to create a mark on the surface. While this is taking place, energy is absorbed and turned into heat, which melts the material. Due to heat absorption, the material’s surface becomes malleable and witnesses a color change. After the surface cools, the change creates permanent markings.

Laser etching isn’t really deeper than .001″, unlike laser engraving. Metallic coats, plastics, anodized aluminum, zinc, etc., are the most highly indicated materials for laser etching. Applications can be barcodes, logos, and decorative.

Key Differences Between Laser Engraving and Etching

| Aspect | Laser Engraving | Laser Etching |

| Material Removed | Removes more material, creating a deep mark. | Minimal material removal changes surface texture. |

| Depth | Deeper (0.02–0.125 inches). | Shallower (under 0.001 inches). |

| Durability | More durable and long-lasting. | Slightly less durable, especially on wear-prone items. |

| Contrast | Less contrast unless material color varies. | High contrast on coated or treated materials. |

| Applications | Industrial, heavy-duty, permanent markings. | Decorative, fine details, and barcode marking. |

Choosing the Right Method for Your Needs

Although both laser etching and laser engraving seem similar, their applications are quite different. With regard to laser etching vs laser engraving, here are a few things you should know:

- Material Type: Consider the material suitable for each laser technology.

- Desired Durability: Opt for engraving for long-lasting marks. Laser etching offers a higher contrast for fine details.

- Budget: Assess costs for both the process and the material.

Generally, laser etching is more suitable for artistic products that require less durable results, while laser engraving produces a highly durable product. Therefore, it is ideal for industrial applications.

Advantages of Using Laser Technology

Modern laser devices are pretty advanced as they integrate multiple functionalities. In this regard, consider the Snapmaker Artisan 3-in-1 3D printer, which not only does the 3D printing but also has laser engraving and CNC cutting all because of its modular and one-minute quick-swap design.

This Snapmaker Artisan has diverse materials that assist with its functions in 3D printing, laser engraving, and CNC cutting. The dual extruder, including Breakaway Support for PLA, allows you to use filaments like PLA, ABS, PETG, TPU, and Nylon. Different lasers can handle wood, metal, leather, and acrylic, and the 200W CNC Module and 4mm CNC bits can tackle precision machining on tough materials.

The Snapmaker Artisan is highly beneficial for users who want an all-in-one solution for creative and industrial projects. By switching between laser engraving, 3D printing, and CNC cutting, users can create artistic designs within minutes.

Let’s Wrapping-Up

Manufacturing technology is constantly changing, and laser processes are now taking the lead. The fact that laser etching and laser engraving offer greater precision, versatility, and durability gives the industry a new dimension. Laser engraving marks are the deepest and most durable, while laser etching, on the other hand, offers better contrast; thus, it will be appropriate for decorative designs.

Choose the one that suits your objective and your materials. For complicated artistic designs, laser etching is the best process to utilize, whereas laser engraving is better suited for industrial-grade durability.

Enhance your facility or artistic endeavor with tools such as the Snapmaker Artisan, a true 3-in-1 machine that transforms 3D printing, laser engraving, and CNC cutting into a single powerful and capable device. This is state-of-the-art technology to plunge you into confidence for your projects!