Useful Things to 3D Print for Daily Life

3D printing is not just about artistic creations. 3D printers are helpful tools for producing practical, functional items that can solve everyday problems and draw you into home manufacturing.

Table of Contents

What can you make with a 3D printer?

Let’s examine three practical examples showcasing the versatility of 3D printing:

Custom 3D Printed Card Box

3D printing offers trading card game enthusiasts convenient customization for their cherished collections. 3D printed deck boxes provide individualized dimensions because they differ from the standardized storage products that exist in markets today.

- Perfect sizing for your collection: Whether you’re storing a standard 60-card MTG deck, a 100-card Commander deck, or any TCG format (like Pokémon, Yu-Gi-Oh!, or Lorcana), you can design boxes with precise internal dimensions.

- Sleeve-friendly design: The design of these storage units allows you to fit single—to triple-sleeved cards while maintaining protective clearance space for easy access.

- Personalized compartments: Create dedicated spaces for tokens, counters, dice, or sideboard cards—all contained within a single storage solution.

- Special aesthetic touches: You can add game logos, character designs, or personal emblems directly into the box structure for your collection.

- Cost-effective alternative: Custom 3D printed storage solutions use only a few dollars for filament. The final product costs less than a premium commercial box. Established brands sell boxes that start at $30 and can go up to $50 per unit.

It might surprise you how much planning goes into sizing these boxes—considering card dimensions (with and without sleeves), deck thickness, and even leaving extra space for easier access. This level of customization simply isn’t available in commercial options. Here is our detailed guide—3D Printed Deck Box Guide for TCG Players.

Adjustable Smartphone Photography Rig

3D printing enables photographers and content creators to design specialized equipment at a fraction of commercial costs. The smartphone photography rig showcases this perfectly.

- Precision photography setup: Create a repeatable way to photograph small objects (like 3DBenchy models) at consistent, fixed angles—essential for documenting your 3D printing journey or product photography.

- Customizable fixtures: Design includes a rotary platform for capturing seamless 360° videos, sliding fixture holders to adjust object-to-camera distance, and adaptable mounts for various smartphone models.

- Professional lighting solutions: Incorporate universal holders for flashlights and light bouncers to achieve professional-quality lighting without expensive equipment.

- Adaptable for various subjects: While initially designed for 3DBenchy models, the rig works perfectly for photographing other small objects like stamps, insects, flowers, miniatures, and toy figurines.

This project is particularly valuable because all components can be printed within common build volumes, making it accessible to most 3D printer owners. The capability to produce professional-grade photography equipment tailored to your specific needs illustrates how 3D printing connects the divide between consumer-grade and professional tools.

Workshop Fixtures and CNC Workholding Solutions

3D printing transforms how makers approach their workshop organization and machining tasks. Custom fixtures such as the Snapmaker clamps highlight the practical benefits of this technology.

- Custom CNC workholding: Design and print specialized clamps, vises, and fixtures that perfectly secure workpieces during CNC operations, ensuring precision cuts and consistent results.

- Project-specific jigs: Create assembly jigs that precisely align components during construction, bonding jigs that maintain pressure during adhesive curing, and inspection fixtures for quality control.

- Cost-effective workshop solutions: Replace expensive commercial fixtures with custom-designed alternatives that use minimal material (typically just a few dollars worth of filament plus basic hardware like M4 threaded rods and wing nuts).

- Rapid implementation: Move from identifying a workshop need to having a functional solution in hours instead of days or weeks—design, print, test, and refine all in the same day.

- Optimized workflow integration: Design fixtures specifically for your unique tools, workspaces, and projects rather than adapting your work to fit standard commercial options.

The beauty of 3D printed workshop fixtures lies in their adaptability. Unlike commercial options that serve general purposes, your 3D printed fixtures can incorporate specialized features like integrated cooling channels, ergonomic handling surfaces, and weight-reducing internal structures. They represent a perfect marriage between digital design freedom and practical workshop application, making your CNC and manual operations more efficient, precise, and enjoyable.

Tips for Creating Useful 3D Prints

Material Matters

When creating functional 3D prints, material selection directly impacts durability, functionality, and appearance.

- PLA: Easy to print and ideal for prototyping, but less suitable for items needing strength or heat resistance

- PETG: Excellent balance of strength, flexibility, and ease of printing. For TCG deck boxes, PETG provides the perfect combination of durability and printing ease. Its slight flexibility prevents cracking while protecting valuable cards.

- ABS: Superior heat resistance and durability. Workshop fixtures and CNC clamps benefit from ABS’s higher temperature resistance and strength.

- Nylon: For parts requiring exceptional strength and flexibility like mechanical components.

More information on filament: 3D Printer Filament Types

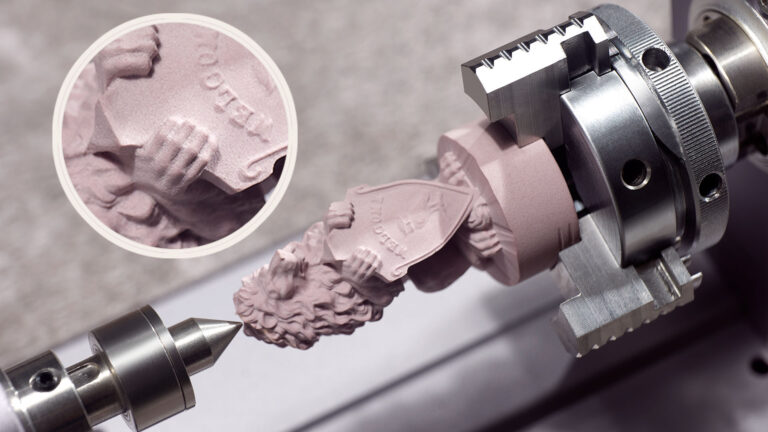

Synergy: 3D Printing and CNC Carving

For maximum workshop versatility, consider combining 3D printing with CNC carving—these complementary technologies create a complete fabrication ecosystem. From a certain perspective, 3D printers themselves are a form of CNC machine, just working additively rather than subtractively. If this idea sparks your interest, you can find further discussion on History of CNC Machines: From Punch Cards to Your Desktop.

- Prototype before commitment: 3D print complex models to verify fit and function before machining expensive materials like hardwood or aluminum

- Create specialized tooling: Design and print custom fixtures, soft jaws, and work-holding solutions specifically for your CNC projects

- Develop perfect models: A complex decorative piece might require 4+ test prints before achieving the perfect design for final CNC production

Multi-function machines like the Artisan 3-in-1 provide both technologies in a single footprint, making this approach accessible even in space-constrained workshops.

Master CAD

While downloading pre-made models from repositories like Thingiverse or Printables is convenient, the true magic of 3D printing emerges when you create custom designs that perfectly address your specific needs. Learning Computer-Aided Design (CAD) transforms your 3D printer from a reproduction tool into a personal manufacturing solution.

The learning curve might seem steep, but start with simple projects—perhaps a basic phone stand or a custom spacer for your workshop. As your skills develop, you’ll naturally progress to more complex designs like articulated fixtures or precisely-fitted deck boxes.

Many beginner-friendly CAD programs offer intuitive interfaces with abundant tutorials. The investment in learning these skills pays dividends across all your projects, allowing you to iterate designs quickly and solve unique problems that no downloadable model can address.

Related guide: How Can You Make 3D Printer Models?

Final Words

Whether protecting trading cards, creating photography setups, or optimizing workshop workflows, practical applications extend far beyond decorative trinkets.

The most useful 3D prints often come from everyday challenges. What problem will your next print solve?