What is G-Code: The Language of CNC Machines

CNC, AKA computer numerical control machines, are taking the industrial world by storm. They perform functions at incredible speeds, saving time and additional costs for the manufacturers and improving precision and churn rates by miles.

The machines are mainly controlled by computers, with pre-programmed instructions installed to perform tasks without delay or human intervention. The medium through which the computers and machines share instructions is known as the G-code, the coding language that offers guidance on tool movements, speed, depth, and other aspects of manufacturing.

Let's look closer at G-code and how it helps machines operate accurately and consistently. This has transformed industries like CNC cutting, engraving, and even 3D printing. So, without further ado, let's dive straight into it.

What is G-Code

G-code, short for Geometric Code, is the programming language used to control CNC machines. It originated in the 1950s as part of early numerical control (NC) systems, and has now evolved to the standard medium that gives machine instructions across various platforms.

Its purpose in manufacturing is to translate design specifications into commands that CNC machines can execute, ensuring consistent and accurate production.

How does G-Code work?

G-code provides consistent instructions for CNC machines, guiding them to perform tasks with high precision. The language itself is very detailed, giving commands for each function of the machine, according to the design created by the CAD software.

Besides being the name of the whole language, g-code is an essential component of the programming language. The main command starts with "G" and dictates how the machine moves. For example, G01 tells the machine to move in a straight line, while G02 and G03 handle circular movements. M-codes control other machine functions, like turning the spindle on or off (M03/M05) or activating the coolant (M08/M09).

Coordinates are integrated into the code that tells the machine precisely where to move while the feed rate specifies its speed, and the spindle determines the speed at which the cutting tool rotates.

An example of a G-code instruction like G01 X50 Y50 Z-10 F1500 means:

- Move straight to the position (50, 50, -10).

- Use a feed rate of 1500 mm per minute.

Common G-Code Commands

G-code consists of standardized commands that instruct CNC machines to perform specific actions. Below is a list of commonly used G-code commands and their purposes:

- G00 (Rapid Positioning): Moves the machine tool quickly to a specified location without cutting.

- G01 (Linear Interpolation): Enables controlled, linear movements for cutting or machining operations.

- G02/G03 (Circular Interpolation): Guides the machine in circular paths, clockwise (G02) or counterclockwise (G03).

- G17/G18/G19 (Plane Selection): Select the machining plane—XY, XZ, or YZ, respectively.

- G90 (Absolute Positioning): Positions the machine tool based on absolute coordinates.

- G91 (Incremental Positioning): Positions the tool relative to its current location.

Additionally, M-codes are used for auxiliary machine functions:

- M03/M05: Turn the spindle on/off.

- M08/M09: Activate/deactivate coolant.

- M30: End the program and reset the machine.

Each command combines specific coordinates and parameters to define precise movements and actions. Understanding these common G-codes is essential for efficient CNC programming.

G-Code in Different CNC Applications

CNC machines come in various types, each specialized for different manufacturing tasks.

CNC Milling Machines

CNC milling machines are generally used for cutting and shaping materials like metal or plastic and have various uses in the automotive, aerospace, electronics, and even the medical industry. They rotate a cutting tool against the material to remove excess, creating intricate shapes, holes, and features. This makes them particularly useful for manufacturing objects of detail with great accuracy.

CNC Lathes

The CNC lathes are the opposite of milling when it comes to cutting objects since the cutting tool remains stationary and the workpiece is the one that rotates. It is used to create less complex objects like shafts, rods, and bushes that are cylindrical or symmetrical in shape and do not require too many details.

CNC Routers

The routers are the milder versions of CNC machines, used on softer material, like wood, rubber, and plastic instead of metal, and are known for working at high speeds. This is due to their large work beds, advanced spindles, and the resident G-code. They are typically adopted in furniture production, sign-making, and prototyping models in product development.

3D Printing

Unlike drilling bits or milling, 3D Printing is an additive manufacturing method that builds 3D objects from the ground up. A 3D printer like the Snapmaker Artisan 3-in-1 is a prime addition to the manufacturing process, reducing waste and enhancing flexibility in your design. The process begins by creating a design using CAD software. The design is then interpreted into G-code using slicing software, which in turn offers guidance to the machine.

Benefits and Challenges of Using G-Code

By removing human intervention in manufacturing, the G-code has livened up things for the industry in many ways, including consistency in the quality of products, the ability to produce goods with great details, thanks to precision, and improving standards for the overall market. This allows owners to focus on other important things, such as strategy, decision-making, and the livelihood of their employees.

G-code is the standard language for many types of CNC machines, showcasing its versatility on different platforms where it can easily be modified to suit specific production needs.

However, it can also be difficult to learn, especially for beginners where the language requires a lot of practice to master. Being an expert in the language is important if you are anywhere near the manufacturing industry since a single error in the G-code can lead to extremely costly mistakes.

While G-code offers incredible precision and flexibility, it also requires careful attention to detail and expertise to avoid costly mistakes.

Future of G-Code and Alternatives

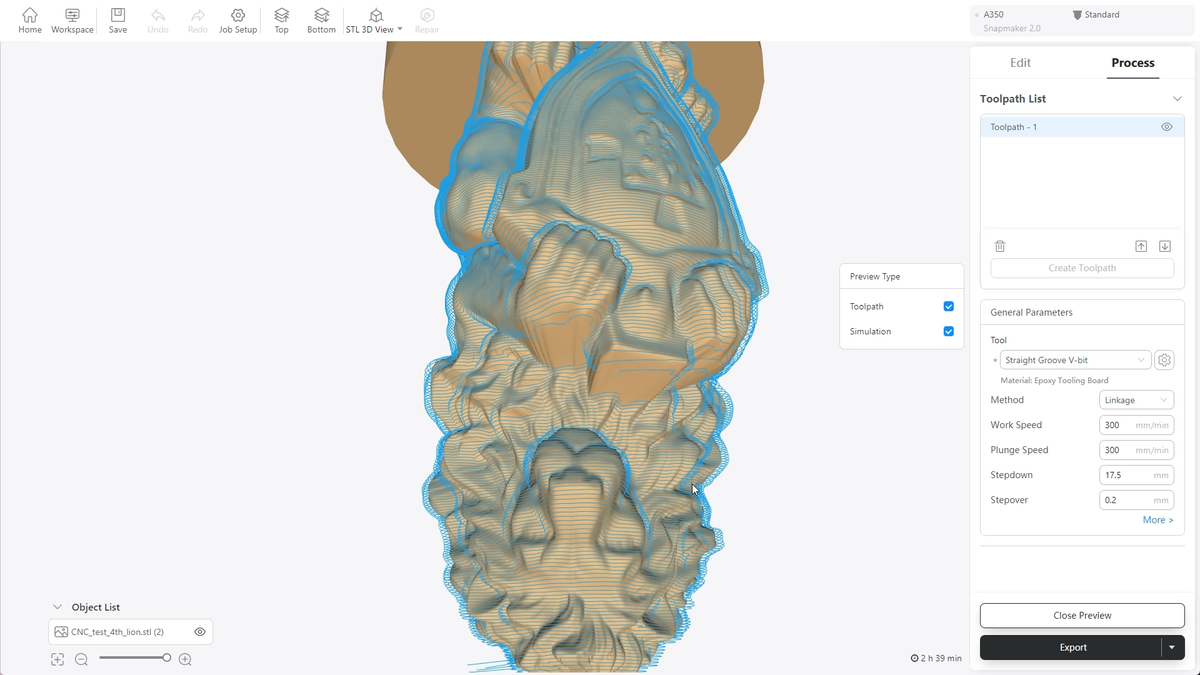

Therefore, the future of CNC machinery and G-code looks more intuitive, thanks to CAM software and its latest advancements. These include solutions that can visualize tool paths and get a basic idea of the product before the process begins, giving users more control over the end product and reducing errors. The G-code is seamlessly interpreted through the CAD design, allowing the manufacturers to focus more on design than solving coding problems.

Developments in AI conversational modules have allowed users to interact directly with machines using natural language instead of G-code, which is becoming more common with CNC machines, simplifying the process for non-experts.

However, despite advancements in AI and technology, G-code is still the primary method CNC machines operate, thanks to its versatility and precision, which allows it to remain the foundation of CNC communication, on which new modules are built.

Conclusion

G-code is the main medium through which CNC machines communicate as the computer delivers precise instructions on which they primarily operate. Despite the integration of CAM/CAD software and robotics development, the machines need an input of G-code for them to operate properly and give out the desired products.

Learning G-code is a valuable investment for those looking to enhance their CNC programming skills. The fact it is the standard medium for a variety of CNC machines allows it to remain a versatile and integral part of the industry. So if you are a manufacturer who wants a better understanding of how the process works, CNC programming newbies who want to improve their skills or just someone who enjoys coding as a hobby, G-code is a good place to start, where it's precise, versatile and often easy to get a headstart, provided you have got a gist of the language. Click here for more knowledge and practical examples about G-code in CNC.