The Environmental Impact of 3D Printing: Is It Sustainable?

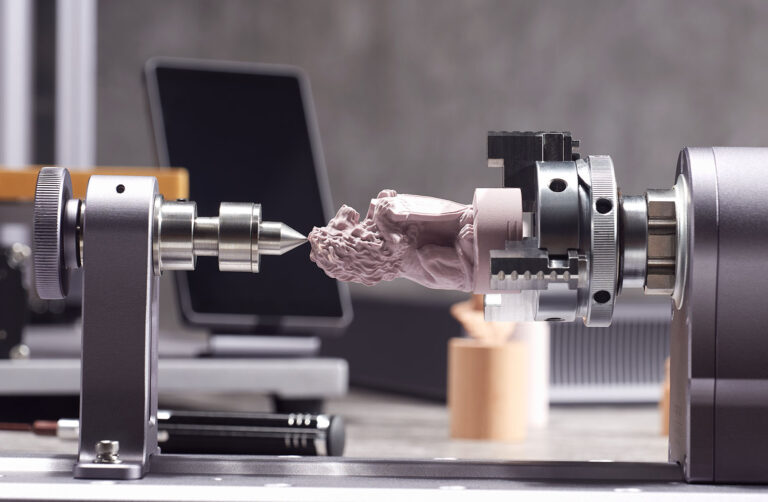

3D printing (or “additive manufacturing” if you want to sound fancy) has completely changed how we make things, from artificial limbs to complex airplane parts. But here’s the million-dollar question: What is 3D printing’s environmental impact, and is it truly a sustainable manufacturing solution? We will discuss the various facets of 3D printing’s environmental footprint.

Is 3D Printing Bad for the Environment?

3D printing isn’t perfect when it comes to the environment. It’s essential to acknowledge its potential negative impacts:

- The Material Problem: Most 3D printers use plastics made from fossil fuels (like ABS and PLA). Sure, you might hear that PLA is “biodegradable,” but here’s the catch – it needs special industrial facilities to break down properly. The production of these plastics contributes to greenhouse gas emissions and resource depletion. Other 3D printing processes use metals. Mining and processing these metals can tear up habitats and cause pollution. It’s not just about what comes out of the printer – it’s about where these materials come from in the first place.

- Energy Consumption: Does 3D printing use a lot of electricity? The answer depends on the specific technology and the size of the print. Some methods, like FDM, are relatively energy-efficient for small prints. However, larger prints and processes like SLS and metal 3D printing can consume significant energy. This energy consumption contributes to carbon emissions, especially if the electricity is generated from fossil fuels.

- Waste Generation: There are several ways 3D printing can create waste:

- Failed Prints: Prints can fail for various reasons, resulting in wasted material.

- Support Structures: Many 3D prints require temporary supports to prevent collapse during printing. These supports are often discarded after the print is complete.

- Material Scraps: Some processes, particularly those involving powders or filaments, can generate material scraps that may not be easily recyclable.

- Emissions: 3D printing processes that use some plastics or metals can discharge volatile organic compounds (VOCs) and ultrafine particles into the air. Out of these emissions can pollute the air and have adverse effects on one’s health in poorly ventilated environments.

Is 3D Printing Environmentally Friendly?

Despite these challenges, 3D printing also offers significant environmental benefits:

- Less Transportation: By enabling local or on-demand manufacturing, 3D printing helps tremendously reduce the need for long-distance shipping. Think about this: by printing a custom-designed gift instead of buying a mass-produced product from a store, I remove the environmental impact from packaging, storage, and transportation across long distances. Also, in offices, workshops, or homes, you can easily place 3D printers for smaller items, which means local manufacturing of parts, prototypes, and finished goods. That means fewer trucks on the road, fewer ships crossing oceans. This lowers fuel consumption and associated carbon emissions.

- On-Demand Manufacturing: This is huge for sustainability. Instead of factories cranking out thousands of items that might never sell, 3D printing lets you make exactly what you need, right when you need it. It’s like the difference between cooking a huge pot of soup that might go bad versus making just enough for dinner. This is particularly beneficial for spare parts, customized products, and low-volume production.

- Lightweight: In industries as diverse as aerospace and automotive, lighter components can be created through 3D printing. That saves fuel and increases energy efficiency of vehicles and aircraft.

- Use of Recycled Materials: More and more people are using recycled plastics for 3D printing. When you combine this with energy-efficient printers, you’re often using less power than traditional manufacturing methods like injection molding. Plus, it keeps plastic out of landfills.

3D Printing and Sustainability

The future of 3D printing lies in embracing sustainable practices. This includes:

- Sustainable Materials: Research and development are focused on creating more sustainable 3D printing materials, such as bio-based plastics derived from renewable resources and recycled filaments.

- Recycling and Waste Management: Improved recycling methods and waste management strategies are crucial for minimizing the environmental impact of 3D printing. This includes developing closed-loop systems where waste materials are reused in new prints.

- Future Trends: Emerging trends, such as more energy-efficient 3D printing technologies and the use of more sustainable energy sources, hold promise for further reducing this technology’s environmental footprint.

Remember: It must be admitted that 3D printing at this stage does not show obvious environmental and sustainable advantages compared to traditional manufacturing, and sometimes it is even more wasteful due to printing failures, etc. But this is the pain. Sustainable development requires coordination across the entire value chain, including manufacturers, suppliers, and market demands. Unlike traditional subtractive manufacturing, 3D printing can produce stronger, lighter, and more sophisticated parts. As the technology matures, materials science advances and adoption widens, 3D printing’s potential to reduce waste, minimize transportation, and enable more efficient resource utilization will become increasingly realized.

Why Hasn’t 3D Printing Been More Publicly Used?

While 3D printing has made significant strides, several factors contribute to its limited widespread public adoption, especially for everyday products and large-scale applications:

- Cost and Accessibility: While desktop FDM printers have become more affordable, industrial-grade 3D printing remains expensive, limiting access.

- Technological Limitations and Material Restrictions: Desktop FDM is limited in material choices, speed, and precision. Industrial 3D printing offers greater capabilities but at a higher cost. As industry professionals note, there is still a need for advancements in material properties, especially in areas like flexible elastomers, and improved surface finishes directly from the printer to reduce post-processing. They hinder efficiency because of current post processing methods such as sanding, polishing, and painting, yet these add time and labor.

- Lack of Awareness and Understanding: Many people are still unfamiliar with 3D printing’s potential.

- Infrastructure and Scalability: Integrating 3D printing into existing manufacturing requires significant infrastructure changes. Building an industrial-scale 3D printing platform for mass production is not a simple, off-the-shelf solution. There’s a gap between desktop (prototyping, hobbyist projects) and industrial (specialized industries) applications.

- Design and Software Complexity: Designing for 3D printing requires specialized skills and software.

- Perception and Trust: Concerns about quality, durability, and safety can hinder adoption.

- Comparison to Traditional Manufacturing: Traditional methods are generally more cost-effective for high-volume production. While 3D printing excels in customization, low-volume production, and complex geometries, it doesn’t yet fully replace traditional manufacturing.

Concerns about the environmental impact of 3D printing may also limit its wider adoption. However, by focusing on sustainable practices and addressing the abovementioned challenges, 3D printing can achieve greater public use and realize its full potential.

Conclusion

The environmental effects of 3D printing are complex pictures with promising potential. Smart applications of 3D printing—like making replacement parts, custom medical devices, and design prototypes—can cut waste and save energy compared to traditional manufacturing. As the technology gets better and more accessible, it’s paving the way for sustainable, local manufacturing that could transform how we make things.