How to Darken Laser Engraving on Wood: Baking Soda and Borax

Something is enticing about the dark wood effect of laser engraving that you can’t get by painting. The vibe is much more organic and has an excellent finish and depth than usual engraving, but requires more laser power.

However, it’s very easy to burn the wood in the process, which you can remove easily with a few tricks, but you can avoid them altogether with the help of borax and baking soda. There is a whole science behind this cheap hack that will save you from expensive losses, so if you want to learn how to use baking soda and borax properly to darken wood then keep reading.

Table of Contents

- Baking Soda & Borax Laser Engraving on Wood

- General How-to for Darkening Laser Engravings on Wood

- How to Use Borax for Laser Engraving on Wood

- How to Use Baking Soda for Laser Engraving on Wood

- Borax vs. Baking Soda for Laser Engraving

- Important Considerations

- Conclusion

Baking Soda & Borax Laser Engraving on Wood

Baking soda is considered to be milder than borax and has more subtle darkening. The chemical compound breaks under the laser heat, turning to sodium bicarbonate that reacts with the natural pigments on the wood. The process is completed without burning the surface, as sodium carbonate helps distribute the heat evenly over the surface without concentrating on a particular spot.

Sodium borate or borax becomes an entirely different compound under the heat from the laser, turning to sodium oxide and boron oxide. Although it has some protective capabilities, boron oxide reduces the melting or, in this case, the burning point of the wood and allows the laser to darken the wood faster, even with lower power.

The dark and light contrasts in the wood give an enhanced result with greater depths and more definition in your engraving while preventing burning.

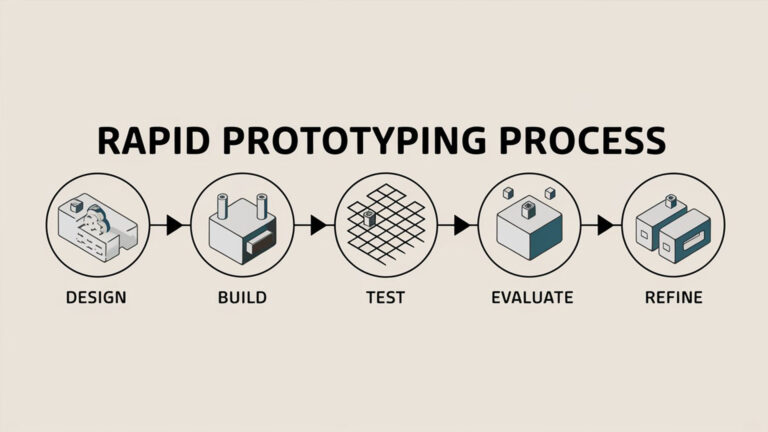

General How-to for Darkening Laser Engravings on Wood

We’ll cover the general workflow here for easy reference. However, don’t miss the practical, detailed instructions for each method in the following sections—they’re key to achieving professional results.

- Prepare your wood surface (clean and sand).

- Choose your darkening method (baking soda or borax).

- Apply the chosen substance.

- Laser engrave your design.

- Clean and finish the wood.

How to Use Borax for Laser Engraving on Wood

Since borax is more reactive, you must be careful when performing this method.

Step 1. Prepare the Borax Solution

You can’t apply the substance directly onto the surface because it won’t work. Mix a tablespoon of borax in 400ml of water and set it aside.

Step 2. Apply the Borax Solution to the Wood

How you choose to apply the solution will also affect the engraving. For example, if you use a spray, it will create a thin, even layer on the wood, allowing for a smoother transition, making the option great for large-scale projects.

However, if you want more detail than a thicker layer, a sponge or brush will help you achieve the desired effect and allow for more precision.

No matter your chosen method, ensure that the area you want engraved is well-coated in the solution.

Step 3. Allow the Wood to Dry Completely

If you start engraving while the surface is still wet, the precision will be reduced due to the uneven layer of the borax. The water will also act as a buffer, not allowing the compound to have its complete effect.

The solution doesn’t take that long to dry, usually around 20-30 minutes at most. You can speed up the process with the help of fans or heat guns, but you don’t get it too close since it can scorch the surface.

Step 4. Laser Engrave Your Design

Proceed with the design as you normally would but start with lower heat and power to be safer as borax can speed up the heating. You can also test an easy design on a cheaper scrap of wood treated with a borax solution, to get an idea of how you should proceed.

It is possible to darken the wood without the borax solution, but the effect will be in different shades of brown, rather than the black you can achieve using this method.

Step 5. Address Potential Smearing (Optional but Recommended)

Borax treatment can sometimes cause smearing of the engraved image. To prevent this, immediately after engraving, apply a coat of clear lacquer spray. This will quickly seal the surface and prevent smudging. Some laser engraving modules are designed with air assist, which helps achieve cleaner cuts.

If your image has been smeared during engraving, you can try to save it. Wipe off the residue gently with a brush before applying a coat of lacquer to prevent further smearing.

Step 6. Seal the Engraving (Highly Recommended)

Want the ultimate professional effect? Then don’t forget to seal the engraving with a durable finishing coat of clear varnish, preferably polyurethane for long-lasting results.

Avoid using oil-based varnishes since they can increase the smudging.

Final Result:

Laser engraving with a borax solution will take the contrasts a step further, with the deep blacks and lighter wood, resulting in professional-looking engravings without much power.

How to Use Baking Soda for Laser Engraving on Wood

The method of using baking soda is similar to the borax solution.

Step 1. Prepare the Baking Soda Solution

Since baking soda is milder than borax, the solution will be more concentrated, where you will use a tablespoon of baking soda in 160 ml of water, and dissolve it completely before pouring it into a spray bottle for easy application.

Step 2. Prepare the Wood

The surface of the wood should be clean and sanded before you apply the baking soda, for it to work effectively.

As you are using a spray bottle to coat the surface, spread paper onto unwanted areas that you don’t want to get affected by the heating.

Step 3. Apply the Baking Soda Solution

Spray the baking soda over the wood in an even layer and let it dry completely before you start engraving.

A wet solution layer is likely to be more uneven, resulting in irregularities and smudging of your engraving.

Step 4. Laser Engrave Your Design

The next steps are pretty simple, where you prepare the design as you do normally and place the wood into the machine. Snapmaker Ray features laser focusing, which allows you to easily finish the calibration within 3 steps.

However, you might need to pay attention to the settings according to the design and the type of wood you choose since the baking soda reduces the temperature at which the laser darkens the wood.

Step 5. Clean the Engraved Wood

Not all baking soda is turned to sodium bicarbonate; some is left on the surface and hardens, leaving a white residue on the design, dampening the contrast.

Therefore, it is important to clean the engraved wood, after you are done with the process. This is pretty easy to do since the residue is mostly powder or soot that you can wipe off with a brush or a damp cloth.

Borax vs. Baking Soda for Laser Engraving

| Feature | Borax | Baking Soda |

| Color Depth | Deeper, near-black, but potentially uneven | Relatively even, but not as black as borax |

| Evenness | Potentially uneven, especially at grain changes | Relatively even |

| Concentration/Power Impact | Requires higher laser power for optimal results | Increased concentration significantly improves results |

| Specific Issues | Limited penetration (needs higher power), unevenness | Causes wood to yellow |

| Best For | Applications requiring deep black tones | Applications requiring evenness and where overall yellowing is acceptable |

Important Considerations

Baking soda is relatively safe, but you might want to be more careful while using borax since it’s stronger and releases toxic fumes under the laser.

You can also test drive the two compounds on scrap wood before proceeding to your real project which will give you a better idea of how to work with the chemicals.

Both baking soda and borax are great for darkening wood. However, they may not be very effective on other materials like metal or glass, so you might want to reconsider using either of the chemicals on them.

Conclusion

Using baking soda or borax laser engraving is a sure way to upgrade the final look of your projects with the contrasts that give it more depth and definition.

If you are a beginner but still want to incorporate the light and dark effect on your engraving, you can start with baking soda since it’s milder and easier to work with. However, borax has a deeper contrast that seasoned woodworkers can easily work with.

Both methods improve your art, so don’t be afraid to try them and choose the one that works best for you.